WORK

IN PROGRESS

2019 update

It was my

intention when starting this page to provide a chronological photo essay

of the construction of the layout. Unfortunately I was lax on keeping

this page updated and over a decade lapsed since the last update. Part

of this was due to the somewhat sporadic nature of the construction with

great strides being made some years and very little in other years due

to life getting in the way. In the early days photos were taken with a

film camera then scanned into digital format for use here. This became

easier with the acquisition of a digital camera but it also meant that

the digital camera output often got stored of a number of different

computers and backed up on a considerable number of solid state storage

devices and when it came time to do a ten year update it became quite a

nightmare to find and organize things into the order in which they

happened. In some cases either I've lost track of some of the

progress photos or just never took any. What follows after the

photo from the fall of 2001 is the best I can construct from what I have

found so far. If more archive data is is found I will fit it in with the

rest.

In the

beginning...

The first spike

was driven early summer 1997. The RC&G uses code 332 aluminum rail

which is hand spiked to 1/2" x 1" wooden ties. The ties are double

height which allows for more ballast to cover the base to which they are

attached and protect it from UV rays which tend to do the most damage to

treated lumber. Tie size and rail code were chosen giving preference to

durability over scale appearance. The ties are attached to 3/4" treated

plywood which has been cut to a width to match the ties. Ties are

attached using annular ring nails. Ties are milled by the RC&G shops

from treated lumber and then stained to give the appearance of creosote.

Each section is approximately 8' long and built on a bench. The sections

when complete are floated on 2 - 4" or more of crushed limestone

depending on the amount of fill required and ballasted with 1/4" and

finer crushed limestone.

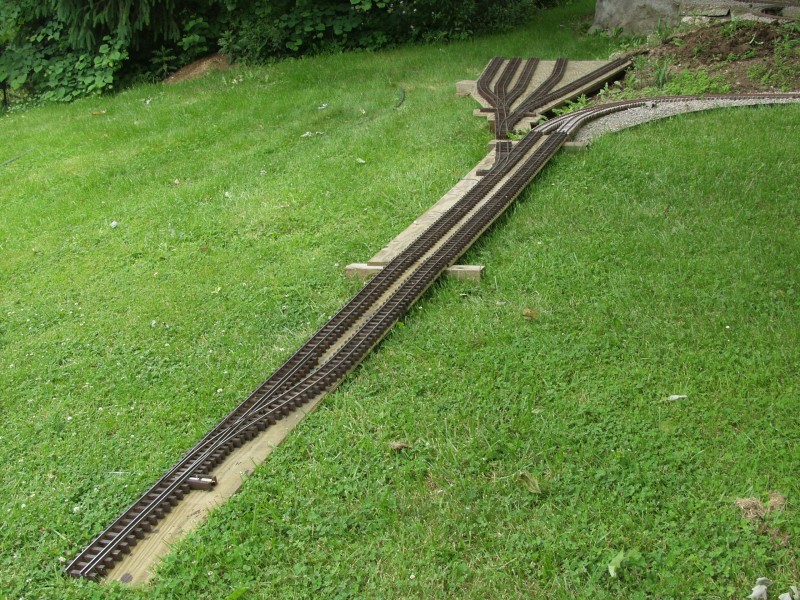

1997

This is where it

all started. The trestle was the first thing built. Pressure treated

plywood was cut in the 'S' shape the trestle was to take and it was

marked for the locations of the bents. The bents were also made from

well dried PT lumber and assembled in a jig using glue and finishing

nails. Once completed they were attached to the plywood base and the

stringers and cross bracing attached. The ties were then attached and

the rails spiked down. The lead in track was built and when complete

construction began. The stake in the front set at the highest

point on the line is used as a reference to set grades. Track is level

till it reaches the trestle and then begins a 3% decent. Stakes toward

the rear mark reference points at 1" increments of decent.

The

first train to run on the RC&G

The next photo

shows the extent of trackage as of October of 1998, mostly weed grown.

Unfortunately the Summer of 98 was filled with higher priority projects

and the railroad saw little in the way of progress.

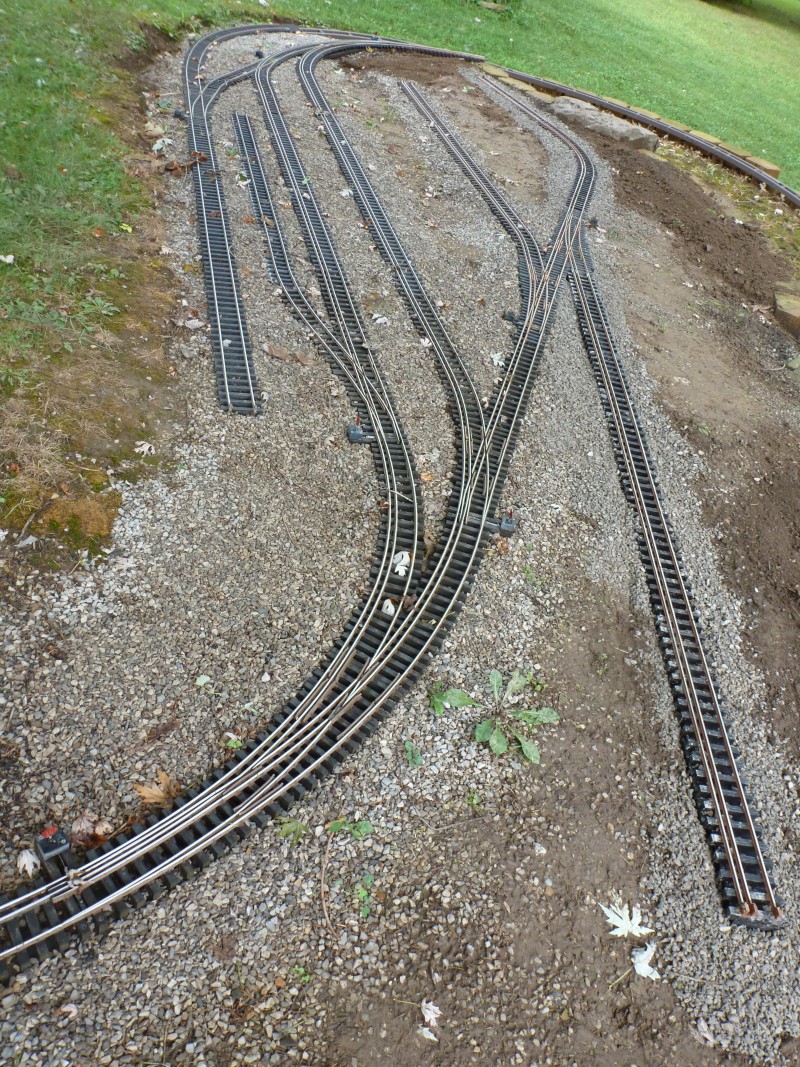

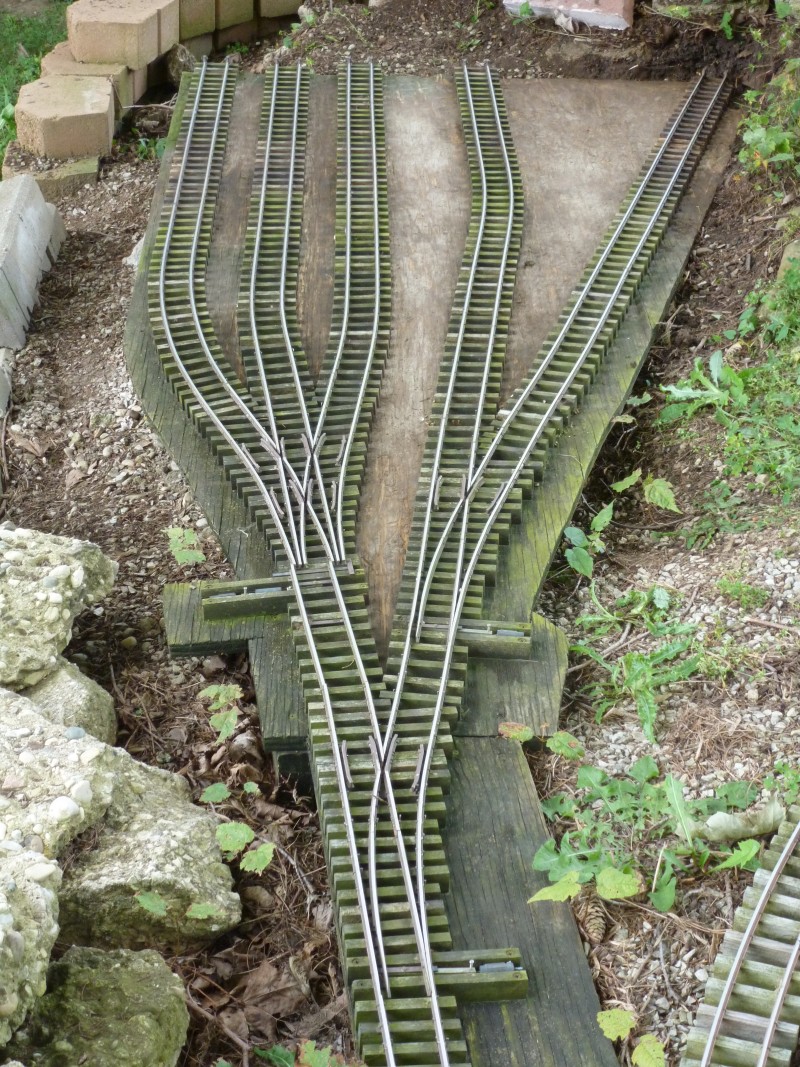

During

January of 1999 the north end of the main yard at Summit was built, this

photo shows it set into the position it will occupy when favorable

weather returns. The switch ties have not been stained pending

installation of Del-aire switch machines.

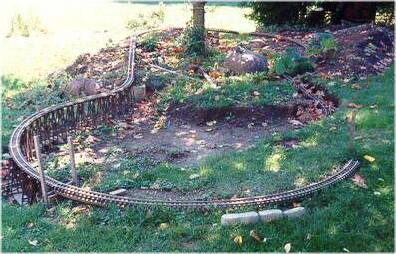

The summer of 99

proved to be much more productive than that of 98. A change was made in

the overall plan that converted this end of the line into a return loop.

This required a lot of fill and a retaining wall to be built. The work

on the yard at Summit was completed and installed as well as the

additional track work required for the loop. The photos that follow show

how the line looked at the end of season 1999.

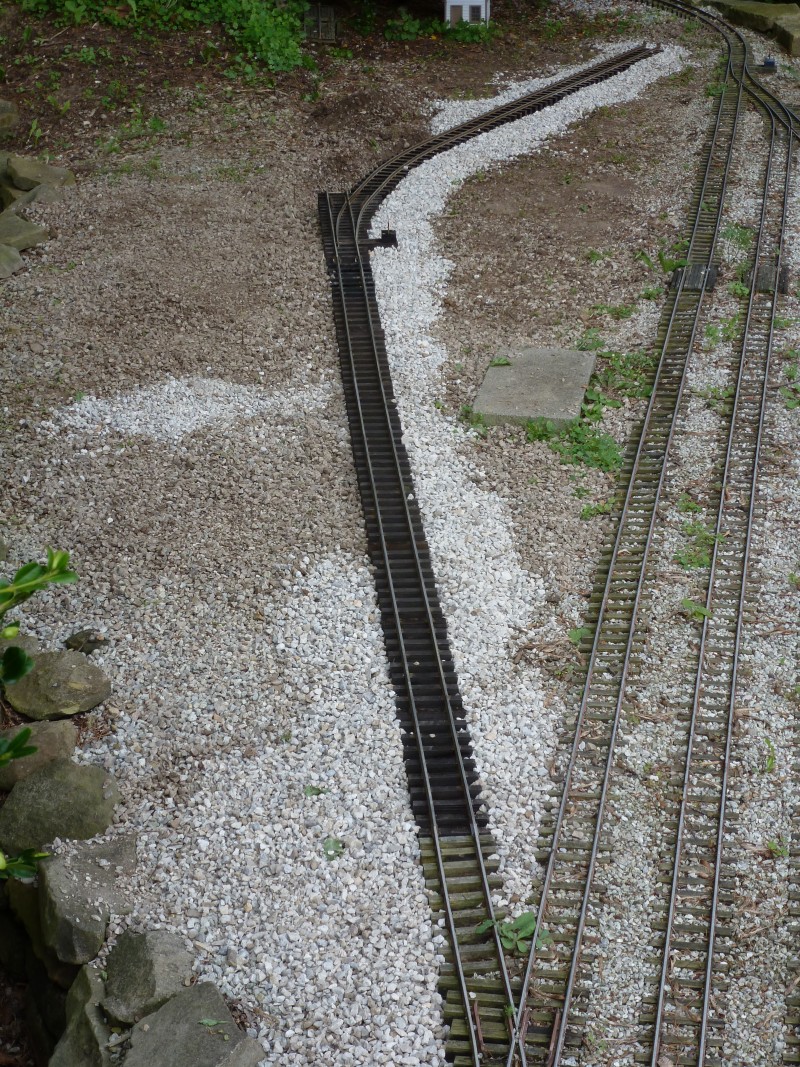

This shot shows the southern end

of the yard at Summit. The track to the far left is nearly a foot lower

than the yard and is descending down Raccoon Gully. The branch going off

towards the rear is a spur to service a retail coal distributor, The

Ohio Valley Coal Company and the RC&G freight office.

This is another

shot of the yard with a train descending the grade down Raccoon Gully.

Where the doodlebug is parked will be the location of the station at

Summit.

This shot shows

the coal dump that will service the Ohio Valley Coal Company.

This shot shows

RC&G #7 working hard upgrade to the yard at Summit. Stone work is

part of the retaining wall built to retain the fill at this point on the

line.

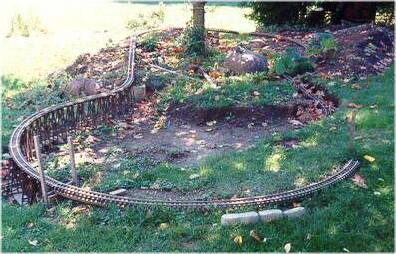

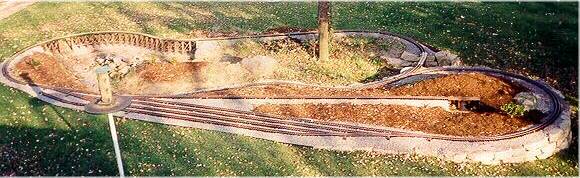

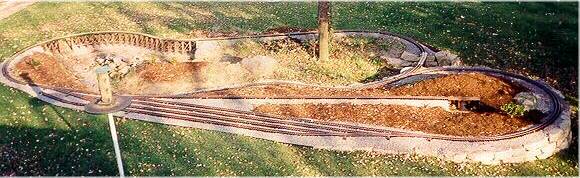

This is an

aerial view of the RC&G at the end of Summer 1999, for reference the

total length from side to side in this shot is forty feet.

From the Fall of

1999 till the Summer of 2001 most of my available layout building time

was consumed by family issues and no further work was done until the

Fall of 2001 when the first part of phase two was added. This section

starts where the line passes under the "S" curve trestle and consists of

a curved turnout leading into a passing siding and the track work which

will become the RC&G's engine servicing facilities. Included in this

is a 3 way stub switch.

The building is the power plant

for the engine facility. The 2 stall engine house will be located at the

end of the two tracks next to the power plant. The power plant

building sits over a junction box where air and electrical services from

the garage are located.

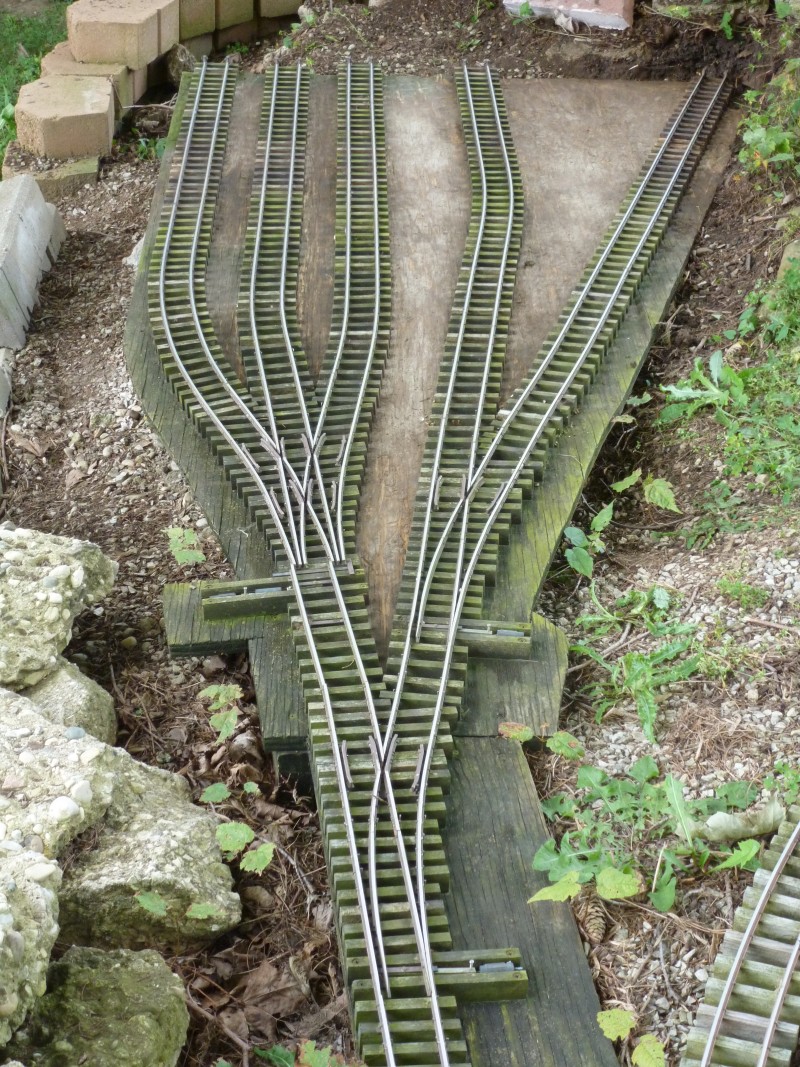

Above the end of

the track in the above shot the track curves to the left and enters the

town of Lynville where the Rockhill mine, the source of most of the

RC&G's income is located. Before I could begin work on this section

I needed to fabricate the track work for the mine coal cleaning plant.

There was another couple of years with little or no new progress but

during the winter 2003 -2004 I finally fabricated the mine track work.

The three tracks to the left service the loading tracks for the coal

cleaning plant, the other two serve to store empties or loads as

required and the fourth track from the left also provides loading for

the waste from the cleaning process.

This

piece and the next portion of the line was set in place in 2004. At the

far end starts the beginning of the dual gauge interchange.

A

view from the other end. At this point everything was just set in place

to get an idea of what was needed in the way of fill and other

landscaping features. Much needed to be done especially in the way of

retaining walls as this track work at this point set on the edge of a

slope.

Also

completed in 2004 were the beginnings of the dual gauge interchange with

first two of the most challenging switches built to this date a curved

and straight dual gauge.

The

narrow gauge branch to the left will be an interchange track for

transferring freight between the gauges.

In

2004 a major retaining wall that would level the ground in the area I

intended to enclose the balance of the layout was started. A planned

home improvement project that would expand the house's foot print would

create a fair amount of fill from excavations for the foundations and

crawl space and I needed some place for that to go. It was only

partially completed, just enough to retain the fill I had and much of

the balance of 2004 and much of 2005 was consumed with the house

additions. Some work was done both on layout and other layout related

projects. I either didn't document much of what was accomplished or if I

did I have lost the photographic evidence of it. If any of it turns up I

will add it here. From 2005 through early 2009 the layout stagnated

except for occasional maintenance. My Wife's health was in decline and

between work, housework, yard work, grocery shopping and taking my Wife

to doctors and caring for her, I just didn't have time for much hobby

work of any kind. After she passed in early 2009 and for the balance of

the year my life was pretty much in turmoil and I had little to no

interest in doing anything hobby related. Finally in 2010 I began to

snap out of it and started getting back into things.

First thing that needed done was completion of the main retaining wall,

the photo below shows the wall after it was completed but before the

balance of the fill was added. In the foreground can be seen the stacked

retaining wall that was built to level and retain the area around the

mine and the area where Lynville will be located. Note that the height

of the main retaining wall at the corner near the shed is nearly six

feet high.

Here

is another view.

In

the fall of 2010 I had fill trucked in, the first of three truck loads

is shown below.

And

I rented one of these to do the heavy lifting.

The

end result is shown next.

It

can be seen in the above photo the end of the track work at

Lynville and the beginning of the dual gauge interchange as been left at

the mercy of the elements and has set mostly untouched for years and not

properly set allowing it to become warped and twisted and this would

need to be corrected before additional work could be continued. From

late 2010 to 2014 I have very little in photos and it seems that not

much was accomplished. This could have been the result of a number of

things including getting my social life back on track. I retired at the

end of 2013 but early in 2014 my former employer hired me back as a

consultant and the first four months of the year saw me putting in a lot

of hours doing consulting work. When that was finished though I started

attacking layout projects with a passion and I have a bunch of photos

from that year so we'll pick up things from there.

2014

2014

ended up being as much a year of rebuilding as it was building anew.

Even the newest portions of the layout were now 10 years old and during

that time were only given minimal love and some areas were in need of

freshening up and restoration. The idea of using taller ties to keep the

substructure covered with ballast and out of the deteriorating UV rays

of the sun had failed in some areas due to my lack of diligence in

keeping said areas properly ballasted. Also some areas I felt could be

improved both from track design and landscaping. The first area to be

tackled was the track work and landscaping at the Rockhill mine. The

photo below shows what it looked like after it had been cleared of mud

and debris it had accumulated in the decade since it was installed. The

area had never been properly ballasted as I wanted to cover the area

with real crushed coal. For the most part everything was still

sound but there were some deteriorated ties and the upper surface of the

PT plywood had suffered from sun exposure. Notice that the switches were

still air powered. Something I had abandoned for the most part several

years earlier. Also the stacking block wall on the left was failing most

likely due to an insufficient base when originally installed.

The

first thing done was to disconnect the section from lead track and

inspect the underneath side. Fortunately the PT wood was all completely

sound there so only the top side would need work.

The

entire section was then moved to the track work bench in the shop where

the necessary work could be completed at a comfortable height. In the

next photo the point ties have been removed for replacement along with

air actuators. One of my inspectors is busy checking it out.

New

point ties have been installed. These are held in place by coated deck

screws. This will allow easier replacement if ever needed.

Any

unsound ties were replaced. The original ties had been nailed in the

area that was covered by the base of the rail, the new ones had to be

nailed outside the rail. The other ties may look rough but it's partly

due to being buried in mud and they still have a coating of it on them.

Once

the new ties were all in the ties and the exposed area was given a coat

of my homemade stain which is a 50/50 mix of oil based ebony stain and

boiled linseed oil. My own designed and built ground throw switch

machines were installed as well and the section is ready to be returned

to the layout.

But

before that could happen the mine site it self needed some work. The

failing stacked wall needed fixed. An additional item on the agenda was

to lengthen the lead track from main as it was found to be a bit short

in actual operational use.

What

I needed was a way to see what all had to be done without hauling the

actual track section out, which is quite heavy and somewhat awkward to

move around. My solution was to make up a light weight frame that

mimicked the size and shape of the section but was light enough to be

easily moved and positioned until I was happy with everything. The photo

below shows the frame. It's setting roughly where I wanted it to achieve

a longer lead track. It was obvious that the stacked wall at the bottom

of the photo would also need to be redone so the whole process became

somewhat of a major operation.

The

next photo shows the frame again after the curved stacked wall had been

rebuilt and moved outward more than the original section of

straight wall. The was to provide more room for the coal cleaning plant

and mine head frame. Some fill had been added and crushed limestone

would be used to fill in both under and around the mine track work.

The

photo below from a different vantage point. Note that the stacked wall

got a sufficient base of crushed lime stone this time around.

The

track work was then set into position and leveled.

A

view from another direction.

After

being back filled and connected back to the mainline the area was

mulched.

A

view from the opposite direction. Note the leaves on the ground, fall

was in the air and though there was more work that needed to be done on

the retaining wall and other things that would need to wait till the

following year.

Another

project that was done in 2014 and was actually completed ahead of the

mine track project was the addition of two sidings in the Lynville area.

The area adjacent to the passing siding was a low area that needed fill

and it looked like a perfect place for some addition industries. This

would mark the first use of ladder road bed on the layout in place of

the up to this point standard PT plywood wood base. This was at least in

part driven by the fact that reasonably flat pieces of PT plywood were

getting to be difficult to find and the fact that the solid vinyl used

in the ladder method was even more impervious to deterioration than the

plywood. At the top of the photo below a new switch was cut into the

passing siding and a short extension built to provide room for

structures followed by a second switch. All of this was done with my

traditional materials, only the two sidings themselves were built using

vinyl ladder and commercial plastic ties.

The

completed track work from both directions, note in the first photo the

disconnected lead to the mine area. These two sidings will eventually

serve four industries, a feed and grain outlet, a shoe factory, a tool

and die works and an oil distributor.

This

wasn't the only area to be refurbished and added to in 2014. The siding

off the main in Summit that serves the Ohio Valley Coal Company, a

retail coal outlet, was in need of leveling and refurbishment and I also

decided that there was some wasted space in the area that could be used

to locate an additional industry. The siding was removed from the main

switch to the point where a new switch would be added. The next photo

shows the area after removal.

The

next photo shows the refurbished track section, the new switch and new

siding. Since this area was all of the older build style the new track

work was built to match. The new siding will eventually serve Perry

Shibbels Meats.

Next

to be tackled was the coal dump. Ten years of the elements with no love

had left it in pretty bad shape. Bad enough that I decided to replace

most of it rather than refurbish.

I

made a new base from PT plywood as I didn't have any plastic material

large enough to do it in one piece but this time it was thoroughly

soaked with my stain / linseed oil mixture. The rest of the pit was made

from 3/4" Trex trim board. The only salvaged part was the deck which was

re stained. The Trex parts were painted with a light tan color to

simulate a weathered concrete. The camera flash washed out the color so

it looks white. Some flat black was sprayed onto simulate staining from

the coal.

Ready

to be installed.

And

set in place and reconnected to the siding.

Giving

the all the track work a test we see # 10 getting ready to switch a

hopper into the coal dump.

And

spotting the hopper over the dump.

This

pretty well covers the progress made in 2014

on the layout itself and set the tone for 2015.

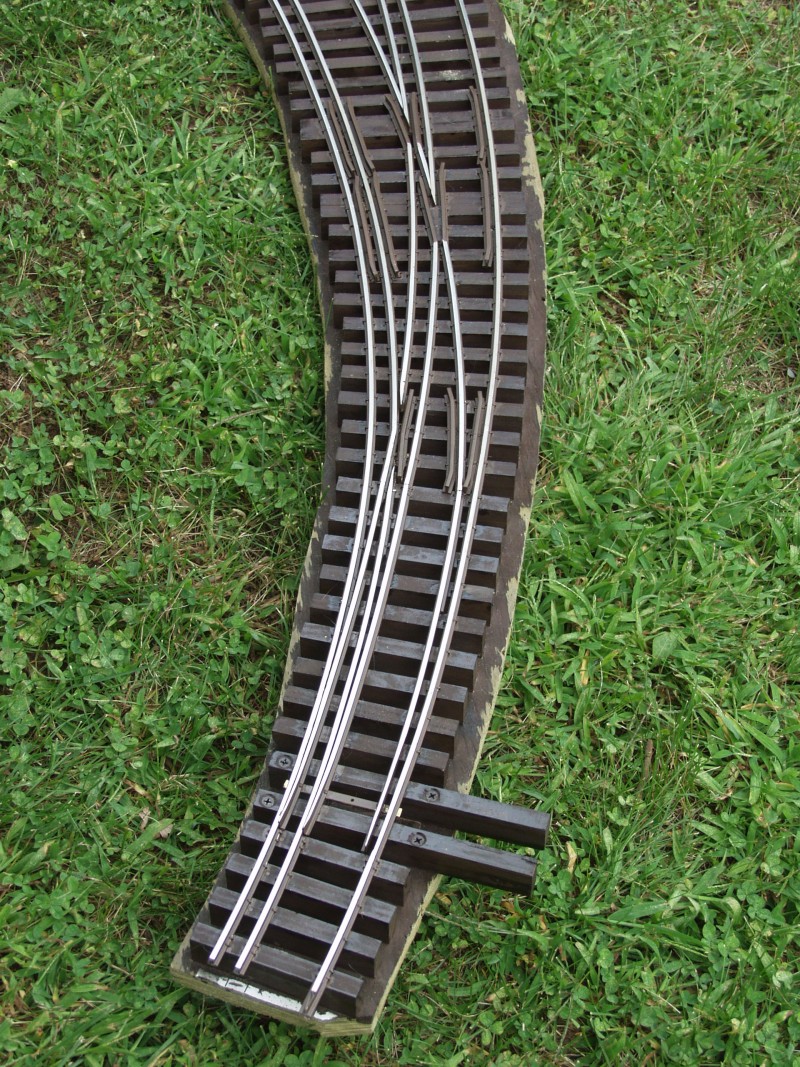

2015 started early in the shop. As I mentioned

earlier the first portion of the dual gauge track work spent a number

of years in a bad situation, only partially supported and exposed to

the elements the base had both warped and twisted. Fortunately some of

this could be fixed by merely soaking the plywood base with water and

allowing it to dry on a flat surface.This fixed most of the issues but

I did end up adding an additional stiffener underneath to keep

everything level. Once flattened out the switch point ties which had

originally be designed to use the Delaire switch machines were

replaced and new switch throws installed and everything was give a

good soaking coat of stain.

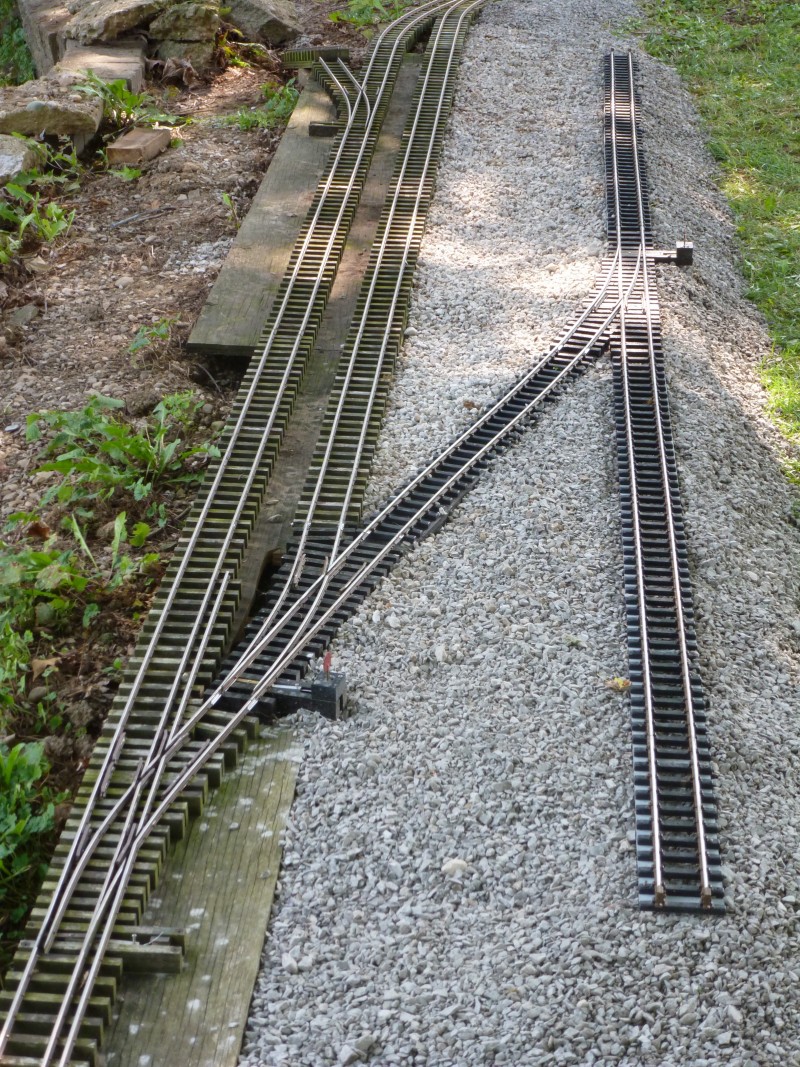

Next up was was building the almost mirror image

section that would be the other end of the interchange. Several years

earlier when I had needed to refurbish the very first section of track

installed on the layout I tried as an experiment using Trex ties. This

experiment turned out so well I decided that all future ties for hand

spiking would be made from Trex. While they don't stain well the

natural gray color looks a lot like old ties especially after they get

dirty. The best thing about them is that I was no longer plagued with

spikes popping up like I had a lot with the pressure treated ties. So

when I started on the last big piece of the standard gauge interchange

I went with the Trex ties. I went with 1/2" by 3/4" on the ties as it

save an addition rip cut. While it doesn't provide the same depth as

the original wood ties I think it will be OK as I now coat the upper

surface of the PT plywood where used. I used a PT plywood base for

this section because I still had a flat piece that was well seasoned

and dry and I like to keep multiple switch installations all on the

same base. The photo below shows the base with ties installed. These

are fastened down using stainless steel finish nails under the area

covered by the rail base and installed with an air nail gun.

The

next three photos were taken during assembly of this section.

Mean

while out on the layout, the photo below shows where the dual gauge

interchange starts and a continuation of the retaining wall which will

hold the fill for the area that will be known as Union. The lumber to

the left is a portion of a tunnel which will be discussed later on.

In

the next photo both ends have been set in place to begin laying out the

area and to determine the length of the interconnecting sections.

At

the other end the approximate position of the standard gauge branch is

located.

A

view from the other end. The track locations marked with paint to the

left will be the interchange sidings the outer being standard gauge and

the inner narrow gauge.

'

I

needed to build a standard gauge switch to complete things and that is

show below.

And

this is roughly where it fits in.

The

stacked block retaining wall for the Union area was extended then I

started fitting the pieces together starting at the current end of the

line.

In

the next photo the wall has been completed as far as the tunnel

entrance.

The

next photo looks back up the main line and shows the mine track work and

the two new sidings added to the Lynville area that was done in 2014.

The patio blocks to the left of the tracks will be where the business

district of Lynville will be located.

And

a photo of the first section from another direction.

Before

anything else could be put down I needed to build up the interconnecting

track sections once I determined their lengths. The dual gauge sections

needed to be hand spiked and for the first time the ties were attached

directly to the ladder rails and the rails were then spiked down. With

the ladder rails being vinyl, the ties Trex and the spikes stainless

steel these section should be maintenance free for a long time. The

narrow gauge section was built using commercial plastic ties which were

attached to the vinyl ladder rails at approximately 6" intervals with

screws. For those interested, in 1/24 scale gauge 1 track scales out to

42". That's why the dual gauge may look strange to those in the know.

Most dual gauge track is 36" and 56" with a difference of 20" between

the two closest rails whereas here there is only a 14" difference. In

1/24 scale standard gauge figures out to 2 3/8" in round numbers.

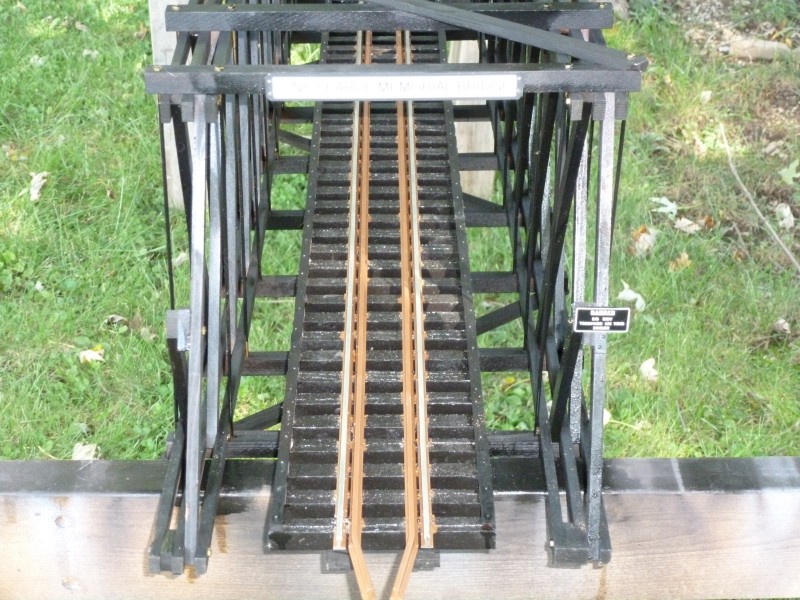

The

next photo shows the length of standard gauge track which will be used

at the gauge change area. At the bottom is the fixture for making

trestle bents that will be needed later in the year.

The

retaining wall was finished and the various pieces put in place.

A

view from the other direction.

The

last section fell just short of the abutment where the trestle approach

to a bridge that will cross over the standard gauge line starts.

A

view from the opposite direction.

A

short section was built up to extend it to the abutment and that would

end the progress on the mainline for 2015.

We

had an extended stretch of seasonable weather that lasted into early

November, as can be seen by the amount of leaf drop on the ground, and I

took advantage of this to work on the standard gauge line. The first

thing I needed for this was an end point to work towards. Mention was

made earlier about a tunnel so I will explain that now. Early on it was

decided that the standard gauge line would only be minimally modeled so

the line exits the interchange traveling down hill and passing below the

narrow gauge line and disappearing into a tunnel where it would

eventually interchange with Bart Salmons West Virginia and Kentucky line

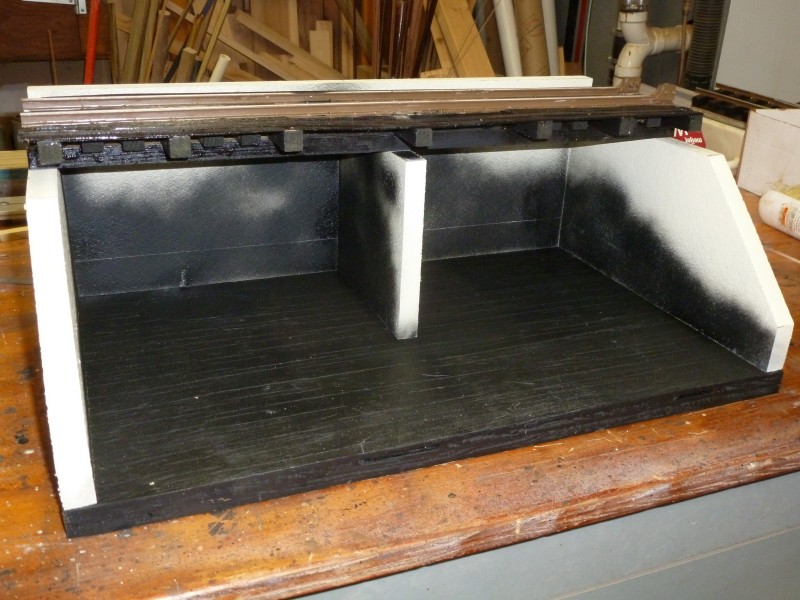

for connection to the N&W. I wanted the tunnel to be long enough to

house a locomotive and three or four cars. The tunnel was fabricated

from 12' long 2"x12" pressure treated planks, screwed and glued

together. One end was plugged then the whole thing buried which ended up

beneath part of the track work at Union as was shown earlier. It is

possible that I may end up storing the standard gauge rolling stock in

the tunnel during off season as the entrance is sealed when its not in

use. Since a tunnel that long with access from only one end is inviting

disaster I needed to be able to be able to extract the track in a worst

case scenario. This was done by spiking rails to ten foot long section

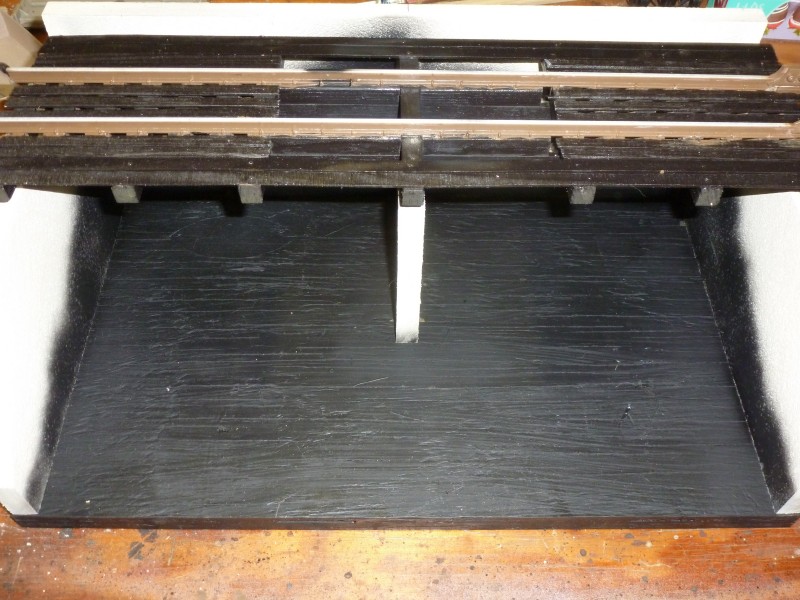

of vinyl trim which would fit between the tunnel walls and could be slid

in and out as necessary. The next photo show the section after

fabrication on the bench. Not shown in the photo is a flat piece that

was added at the end to act as a bumper and to keep cars from sliding

off the end if it needed to be extracted due to a derailment.

And

below shown inserted into the tunnel. I found the section was a bit too

flexible so to stiffen it up some steel angle stock was screwed on down

one side.

With

a target in place the first thing to do was install the ladder. Again

this was made up from 1/2" x 1 1/2" vinyl trim strips. Pressure treated

balusters were used as stakes to bend the ladder around to create the

curve. The photo below shows the start at the standard gauge switch and

the next two photos show it extending all the way to the tunnel. The

retain wall was built just prior to installing the ladder. The radius of

the curve is 8'.

With

that in place I started spiking down the standard gauge track. This was

the most demanding hand spiking done on the layout as it had to be done

in place which meant laying on my stomach to do the first 8' or so until

the ground drops away. The next photo shows how far I got before the

weather went south for the year and marks the end of progress for 2015,

all in all a most productive year.

2016

2016

Started with building the last two dual gauge switches that would finish

the track work at Union. These are shown on the bench in the photos

below after completion.

As

in the previous years I tackled some needed refurbishment work on the

layout before adding new. The first thing done was to fix the track work

at Grinders Switch. The switch ties were newly stained and the straight

portion of the siding totally replaced with plastic ties and then fresh

ballast applied.

Due

to the location of this switch I decided to make it air operated so that

it would not be necessary to step over the trestle to use a manual

switch throw. To do this I used one of the old Delaire machines and

operate it from an air toggle switch. This was mounted in a sealed

electrical box and the toggle handle is protected by PVC pipe cap and is

situated near the edge of the layout as shown in the photo below. It

gets its air from the compressor in the garage which is piped to the

area beneath the power house at the engine facility and from there is

buried to the switch control box and to the switch itself.

The

next area to get some needed attention was the Kitty Wye. This area has

always been only partially finished at best as it can't be properly

completed until a water course (AKA Raccoon Creek) is completed from the

grist mill to the Ohio River. This meant that again substructure that

should have been covered from the sun by fill and ballast was not and

time took its toll. The next three photos show show the wye switch

itself and surrounding track and close ups showing the deterioration.

Note

the multitude of popped spikes which was common with the solid wood

ties.

Some

slabs of an old broken up side walk were used to build up a retaining

wall on one side of the gully allowing more of the substructure on that

side to be covered.

The

wye switch and two leads coming off of it were rebuilt using Trex ties

and some of the PT roadbed was replaced as well. The wye switch retained

its air operator as this switch will be automatically triggered by

trains heading down hill. The method for this will be discussed

elsewhere.

As

part of this control for this I needed to get both an air line and

electrical line across the Gully at this point so two brass conduits

were fabricated and attached to the bridge. The next photo shows conduit

at one end with the electrical cable coming out of it, there is an

identical one on the opposite side with an air line running through it.

This detail is commonly found on prototype bridges carrying water, gas,

electric or communication lines across bridges.

The

next photo shows the area after it was "refreshed", there is still much

to be done here but it won't be done until I finish the work on the

water feature.

With

that out of the way attention was again turned to the dual gauge

interchange where the last two switches for the area were installed. The

next four photos show the installation in progress and completed from

both directions.

In

the above photo the two sidings in the foreground will service the brick

plant and the one in the background the tannery.

Work

also continued on the standard gauge line, ties first then with rail

spiked down.

During

the winter about two years earlier I fabricated the bridge that the

narrow gauge would use to span the standard gauge line. Constructed

entirely from redwood it was built from plans posted here

on George Schreyer's website and is a close in design to a Howe Truss

bridge and it's support system functions as the prototypes did. It was

stored until needed. It was going to be needed soon so this summer it

was brought out from storage and given a coat of my standard stain. The

photo below shows it before staining.

It

still needed the bridge deck built and rails installed and the next

photo shows it after it was installed and the bridge after staining.

A

view from a different angle. The camera wouldn't focus on the lettering

on the sign mounted on the top beam. The bridge is named the "Tiny

Pierce Memorial Bridge" for a deceased friend and fellow garden

railroader who passed too early from complications of diabetes. He liked

bridges and had many different kinds on his layout.

In

order to get from the current end of main line to the point where the

bridge needed to be located a curved trestle needed to be built. The

photo below shows the bents that were assembled using the jig show

earlier. Also there are the heavier duty doubled bents that will support

the ends of the bridge.

I'm

going to show how I went about laying out and building the trestle in

the articles section here. So I will skip

to photos showing the trestle after completion test fitted with the

bridge to check track alignment. Note the it was necessary to continue

dual gauge track partway out on the trestle to allow room for the

switcher room to make a run around move on the interchange.

Now

some of the crazy stuff starts ! I felt that in the future that the

trestle location would be a great photo spot but I really didn't like

the stacked wall that would be in the background on photos taken there.

So I decided to do what the small scale folks do inside and build some

scenery. I had used some hypertufa on another part of the layout years

earlier and decided to do some here as well. Hypertufa is a concrete

concoction that has vermiculite mixed with the concrete. This makes it a

bit lighter and is commonly used to make concrete planters. Due to the

way the stacking wall blocks fit together there are large spaces that

would need to be filled and I felt I could save a lot of concrete mix if

I filled the spaces with foam. So Great Stuff was applied to these area

and when dry the excess was cut off using a hack saw blade free hand.

The result before application of the hypertufa is shown below.

Before

applying the mixture a concrete adhesive was applied of the foam and

blocks to improve adhesion. The mixture itself was colored using

commercially available colorants and was apply by hand (wearing gloves

an absolute necessity) and allowed to cure which takes a bit longer than

normal concrete as the vermiculite absorbs a lot of water. The end

result is shown below. Certainly not perfect but to my eye better than

just the blocks. It wasn't totally cured in the photo and the color will

lighten more when it does. The idea was to simulate the sand stone that

is very prevalent in this area.

In

the next photo the trestle has been set in place, leveled and connected

to the main.

From

another perspective. Note that since the earlier trestle photo had been

taken the guard rails have been installed.

I

found when doing the fill that I needed an extended retaining wall to

better contour the fill and keep it in place. I made up some wooden

forms and cast it in place using mortar mix.

Ties

are making their way closer to the tunnel.

The

lower stacked retaining wall was lengthened to support the fill for the

far end of the bridge.

The

bridge was temporarily set in place to check alignments and level. The

entire standard gauge interchange and the track work to the end of the

bridge is one of the few level areas on the layout.

The

bridge was then removed and the balance of the standard gauge line was

installed. You can also see here that the "scenery" has been extended to

the tunnel entrance.

This

aerial view shows the state of this portion of the layout at the end of

the 2016 building season.

2017

2017

started where 2016 left off. We had some heavy winter and spring rains

and the standard gauge main was in need of some fresh fill and ballast.

Once this was done the bridge, which had only been temporarily installed

the previous fall, was permanently installed. By permanent I'm referring

to the two bridge support bents that were fastened to the concrete

blocks they are sitting on. The bridge rails are attached using Hillman

bridge clamps so that it can be removed if necessary.

More stacked retaining

wall was built to provide the necessary grade for the next section

of main. From the bridge the main needed to descend towards Paiute

Junction and unless I wanted to build a really high retaining wall

and use a lot of fill it would need to be on a trestle for the first

20 feet or so of the decent. The previous fall I had done some

survey work and determined that I would need the line to drop at a

nearly 3% grade to end up at the correct level to tie into Paiute

Junction. I did however make a mistake in this calculation that I

would not find out until to late to reduce the grade.

Like the tunnel was a target to build

the mainline towards I now needed a target for the mainline and this

would be Paiute Junction. At Paiute Junction the mainline would make a

180º turn. There would need to be a passing siding there as well as

the junction switch leading off to the Paiute Lumber Company. All of

this needed to be located very close to a large pine tree and the

ground where it was located was on a slope and full of tree roots. I

decided early on that trying to build this using all on ladder alone

would be an exercise in frustration. In the old days I would have used

my standard method of PT plywood but wanted to try something different

here. To keep the weight down and provide a solid base for the

switches and ladder with the interconnecting track work I decided to

go with an open frame made from PT 2x4's. I constructed the frame work

on my trailer to make it easier to transport to the job site. The gray

rectangles are the Trex bases for the four switches involved. To

increase the rigidity of the frame I used half lap joints on the

second from the front cross wise 2x4.

The next three photos show just how

uneven the location for this was. The first two photos show it in

place and roughly leveled.

The next one shows how it ended up.

Deck blocks were used on the high end to provide a solid foundation.

The other end sits on patio blocks that have been set into the ground

and pinned to keep them from moving.

With that in place the next task was to

build the trestle that comes off the bridge. This needed to be built

on a 3% slope, or so I thought. It was laid out much like the previous

trestle described in the articles section. The primary difference was

adding descending spacer blocks under each section. The first photo

shows it ready for stain and the following one stained with ties and

rails in place and ready for the layout. The trestle is built on a 12'

radius curve and this section is only the first of two required to

make the required turn to align with Paiute Junction.

The first section installed.

And from a different angle.

And an overhead view. The leaves on the

ground signal the end of another building season. Not as much

accomplished but a lot of heavy work slowed progress.

2018

The goal for 2018 was to finish the

mainline track work so I could concentrate on other aspects of the

railroad but in the end it was not to be. We had an over abundance of

rain and ended the year with a record amount of rain fall. This had

two effects on construction. For one all the extra rain kept the grass

growing at a record pace meaning I was spending way more time mowing

and the extra rain made the area that I needed to work in muddy and

difficult to work. Work again started in the shop where the next

section of trestle for the mainline was built using the same method as

used on the first section.

The

next photo shows the finished next section installed. Of note I found

out when I went to install this that it ended up too close to the

retaining wall and didn't line up well with Paiute Junction so a short

straight section was built and inserted between the two curved sections.

An inelegant solution but it worked.

A

view from the opposite direction.

Mean

while, back in the shop the track sections for the track work between

the end of the trestle and Paiute Junction were assembled. This is just

commercial flex track with a difference. To better blend it in with my

hand laid track work the tie strips are cut apart and the tie spacing

increased. This is done utilizing the jig at the far left on the bench.

It has dado's cut in it, ties are set in place and the rail threaded

through them. Once set the rail is painted its rust color using a

generous amount of paint to glue the ties to the rail keeping them in

place until it's attached to ladder frame. Also in the photo can be seen

the four switch blocks for Paiute Junction that have been removed from

the frame to build the switches on them.

One

last short section of trestle was needed to finish it off and eliminate

more retaining wall. It was at this point that I realized the error I

had made in surveying the previous year. Paiute Junction's frame raised

the end point by nearly 6" which would have allowed me to use a lesser

grade and by the time I got to the end of the trestle I had actually

dropped below the level I needed which necessitated a slight incline

between the end of the trestle and Paiute Junction.

A

slightly different angle shot.

In

the next photo the four switches for Paiute Junction have been

completed.

The

ladder frame was assembled and installed to tie into Paiute Junction.I

intentionally let this wander a bit as I think it looks more natural

than dead arrow straight track. This area will be filled to the level of

the track work once some additional retaining wall is built.

I

didn't take any in progress photos of Paiute Junction during the build

process and the next photo shows

it

finished. The bare frame was covered with 1/4" mesh hardware cloth and

then the switches and ladder connecting them was installed. Once that

was in place landscape fabric was installed and ballast and mulch over

that.

Due

to the location three of the four switches would be located in hard to

get to places so I decided early on to make them all air operated. The

panel below was made to contain the air toggles. The box was made from

1/4" acrylic. It has a plastic cover to keep dirt off the panel when not

in use. The cover uses a stainless steel piano hinge.

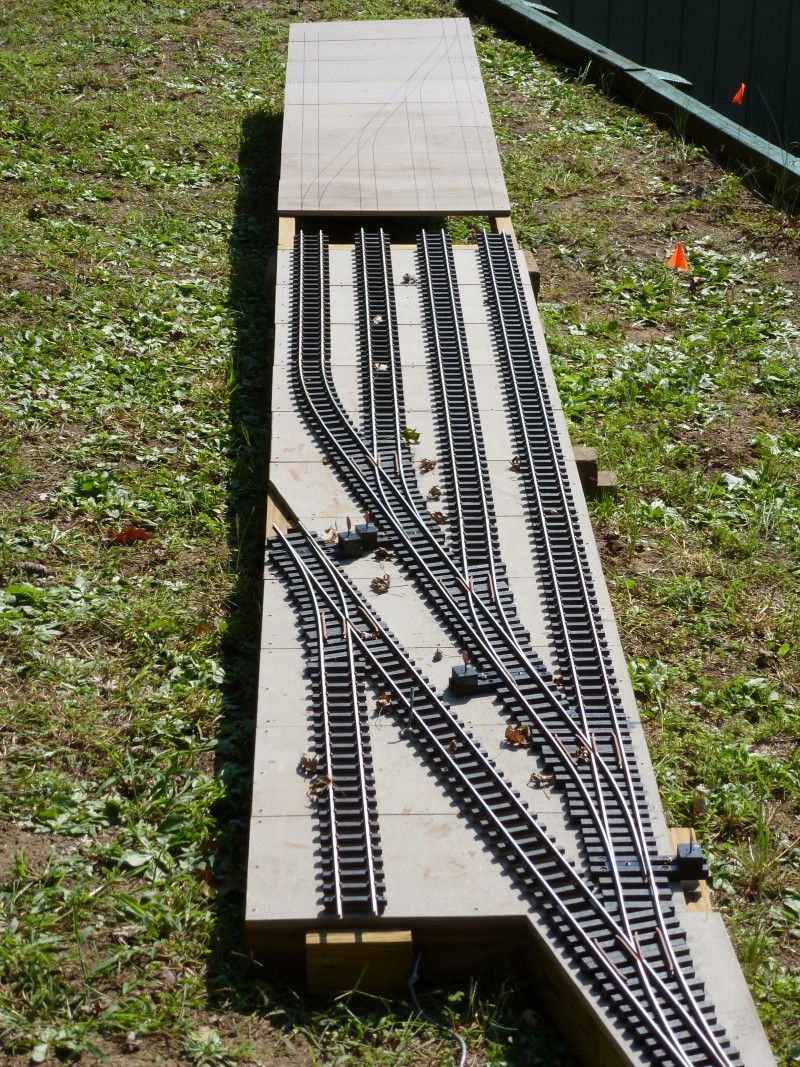

Next

up would be the target for the end of the line. This would be the yard

at Buck's Landing. again this would utilize some new techniques. A frame

work of 2x4 PT lumber was built and the upper surface covered with Trex

trim material. These were installed so as to provide the most support.

The track rail lines were drawn on and the switch ties were installed

and stained. The short lengths between the switches would be hand spiked

but all the longer lengths would be commercial plastic ties.

An

in process photo.

And

the completed section. This is approximately one half of the yard. Doing

it all in one section wouldn't have fit in the space I have to build and

would have been too heavy to move easily.

The

next photo shows it set in the approximate location it will need to be

and temporarily leveled to keep everything flat and true. It was late

September and I couldn't rely on good weather so it needed to be solid

for the winter.

The

second half frame was built and the track plan penciled in. It is shown

in the next photo set in place to allow for holes to be located to

fasten the two sections together once the second half is completed. Once

this was done the second half was returned to the shop. As it turned out

shortly after this was taken the weather again turned rainy and little

else was accomplished after this.

The

only other project to be completed during 2018 was replacement of the

deck girder bridge spanning Raccoon Creek at the Kitty Wye. The bridge

was going to create some issues when I get around to building proper

abutments for it and I had another place I wanted to use it so a new

through girder bridge was fabricated. The side girders were made from

1/4" thick acrylic to which a lot of angle stock was added for detail.

The bridge was based on an actual prototype that was illustrated in

Frank Armstrong's Bridge and Trestle Handbook.

Next

photo shows the bridge deck which was made from PT strip wood with Trex

ties and the rail hand spiked.

The

finished bridge from the top

And

the bottom.

Next

photo show it installed. I removed the conduits carrying the electric

and air lines from the other bridge and attached them to the new one.

Another

view.

And

with # 7 crossing it with a train.

A

fair amount completed but still short of goals. Hope springs eternal

that 2019 is a dryer and more productive year.

Click

here to see the 2019 WIP.

'

'