R C &

G

29

When

I went looking for photos of the earliest bits of construction of this

locomotive I came up empty handed. I could have sworn I took some but so

far no luck finding them. If I do I'll add them at a later date.

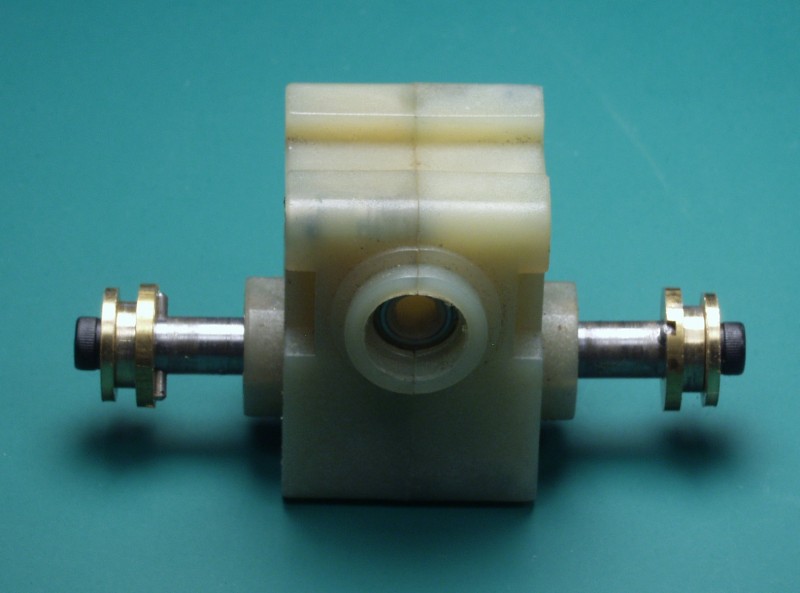

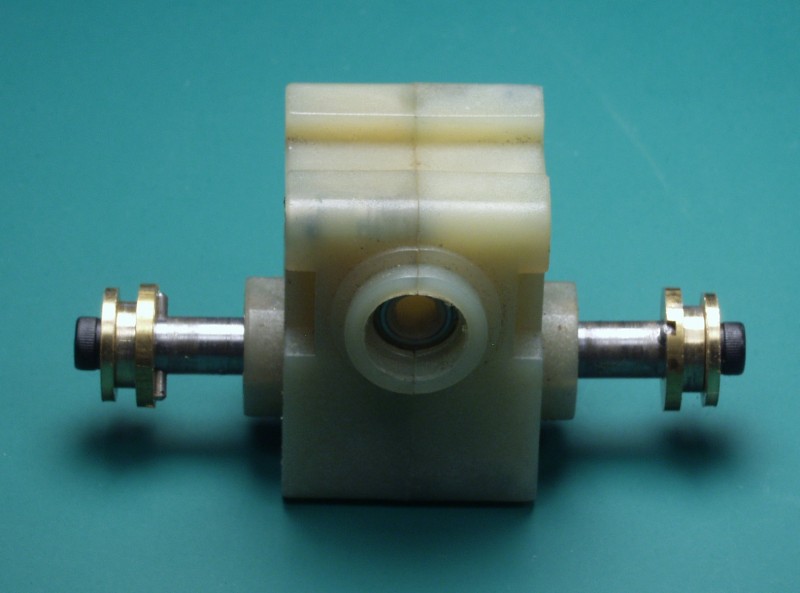

Probably

the earliest photo I found shows the extended axles that I made for the

Aristo gear boxes. It also illustrates the method I use for attaching

the drivers to the axles that allows adjustment of the quartering. I

can't take credit for the method as it is the result of some

communications I had with Barry of Barry's Big Trains, maker of the

famous bullet proof replacement drives for Bachmann Annies. He never

supplied a drawing and what you see is my interpretation of his

verbiage. Since I've never seen one of his drives I can't say how close

I came to replicating it but it works great so I'm sticking with it. The

axle is drilled for dowel pins. Note they do not need to be offset like

I did here. Their location is critical as the will ultimately determine

the gauge of the drivers when assembled. Some adjust can be made by

altering the dimensions of some of the other parts but it's no fun to go

back and machine them a second time so it pays to measure carefully and

do the math correctly.

After

the dowel pin the next piece, machined from brass, has a slot milled in

the back side of it that fits into the dowel pin and keeps it from

rotating on the shaft. The hole through the center is a slip fit. The

smaller diameter portion of this piece fits into the back side of the

driver. The length of this section is such that it doesn't quite extend

all the way to the outer side of the driver face. The last piece of the

puzzle it a brass washer that fits into a recess bored into the face of

the driver. The driver is then placed on the axle bushing, the washer

goes on next then the socket head cap screw goes next. When the screw is

tightened it clamps the driver to the axle bushing by lieu of the

fact that the center part of the bushing is slightly short of the driver

thickness at that point. While initially I wasn't sure this would be

adequate to hold the driver in quarter, so far testing on rollers has

shown it works fine.

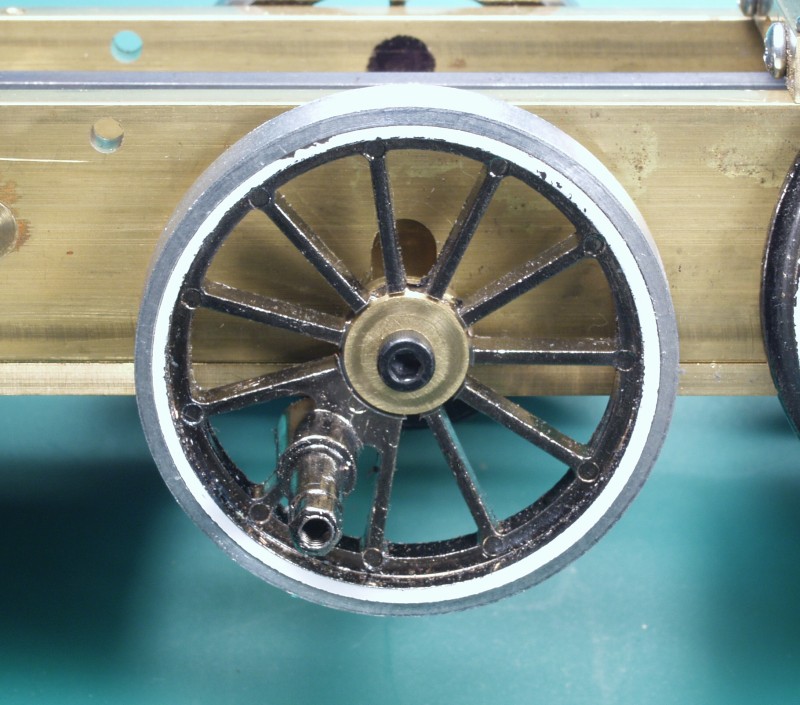

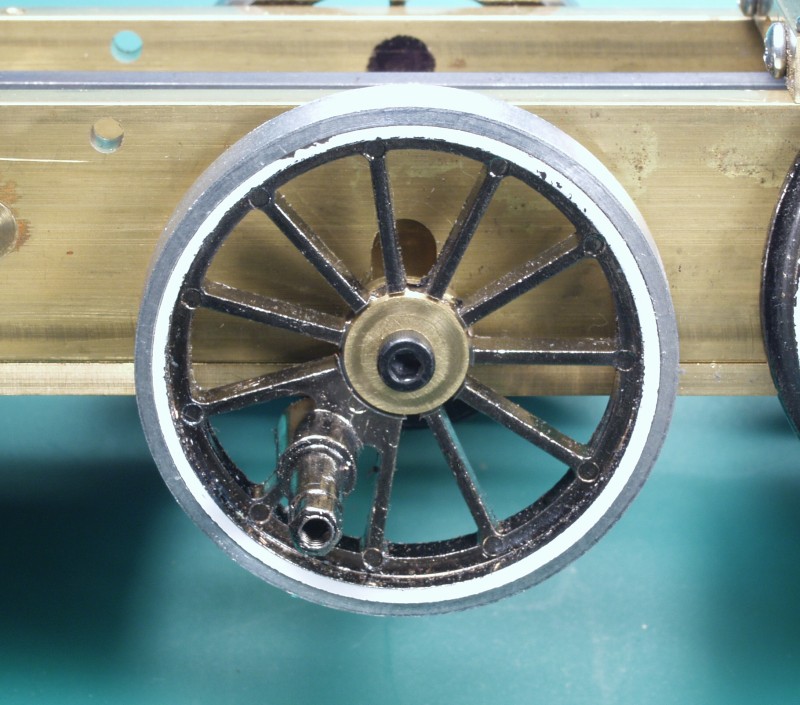

The

next photo shows the driver mounted to an axle. This is the center axle

so it doesn't have a gearbox but the plain axle is done the same way.

The clamping surface seems to be large enough to keep it from slipping

when the screw is torqued down snugly. Also note this center driver has

been fitted with an aluminum tire to bring it up to the same diameter as

the other drivers. These are from a Bachmann Annie. The center driver on

those is made smaller to help keep the others on the rails when going

over grade transitions. On this locomotive the center driver is sprung

so that is not an issue.

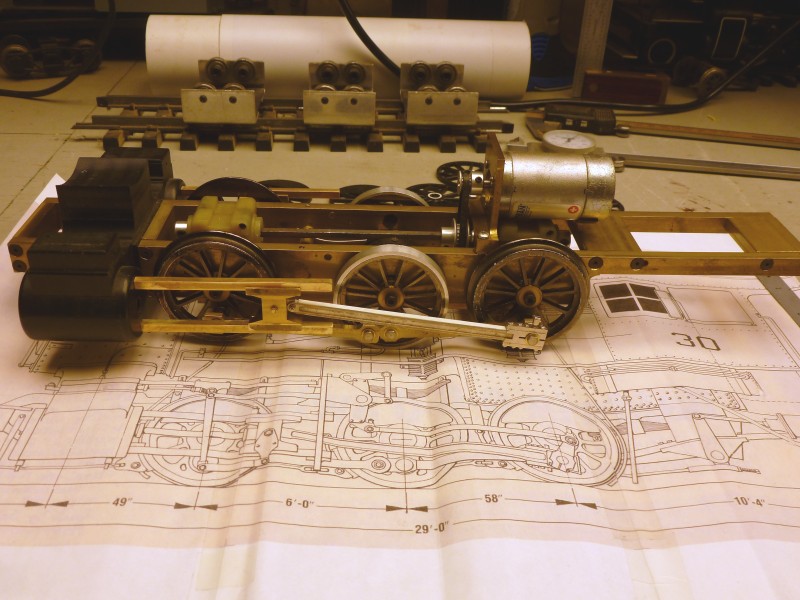

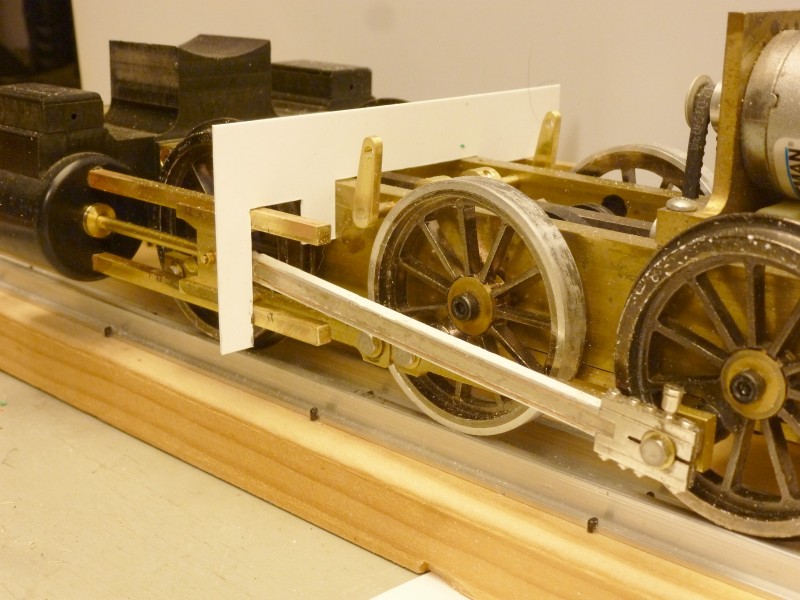

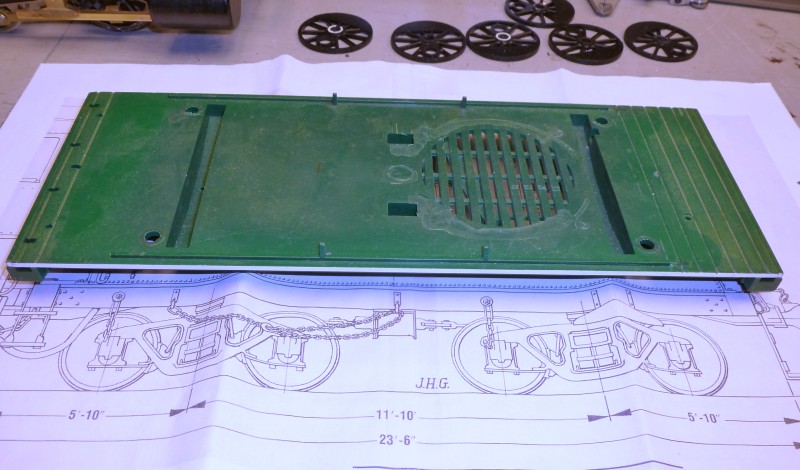

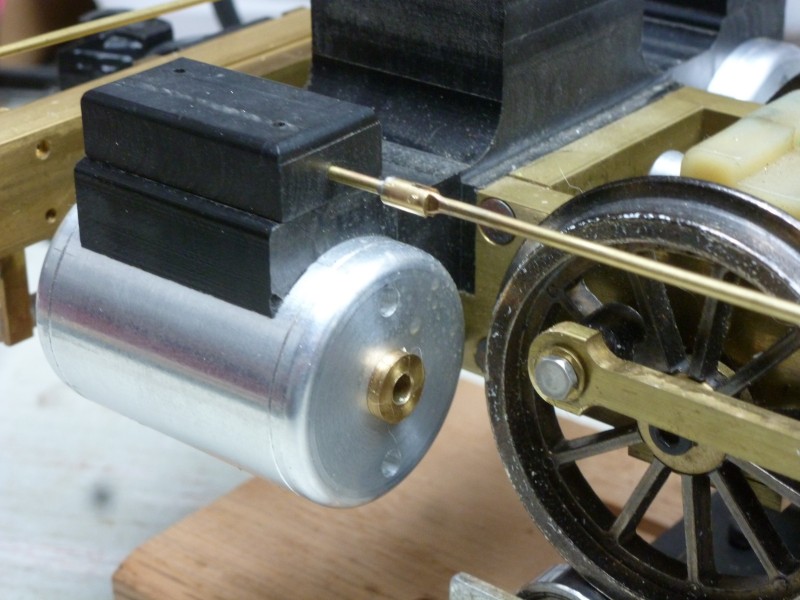

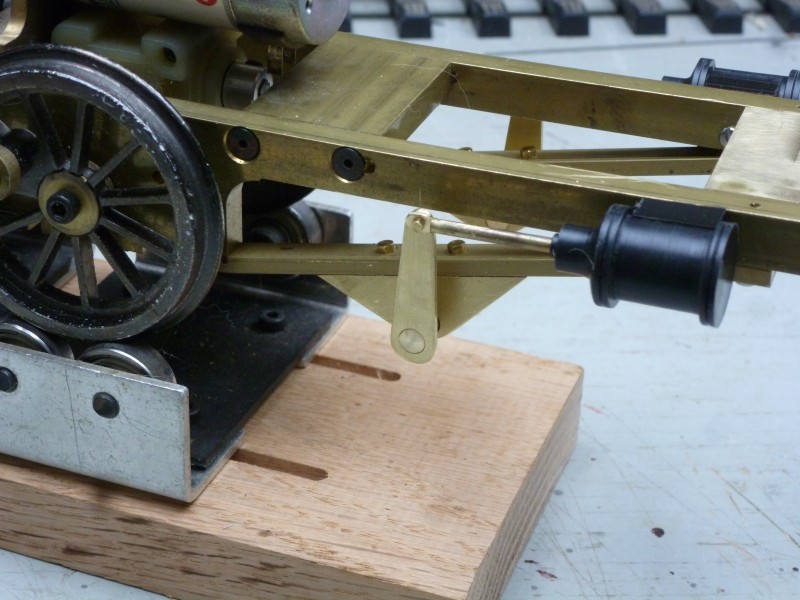

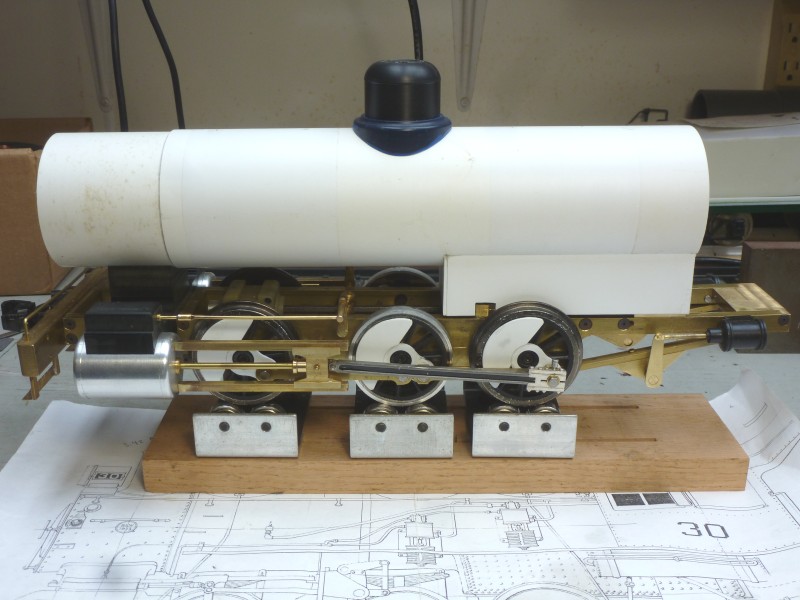

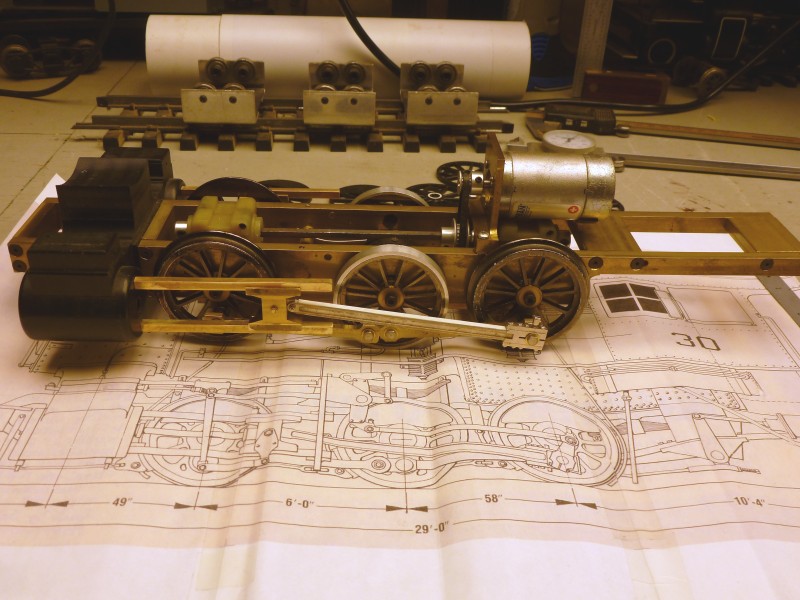

So

far this is the earliest photo of the frame I've found. At this point

the drive has been installed. Since the gearboxes have ball bearings for

the axles I just used friction bearing in the frame. I don't see this

locomotive ever accumulating a lot of mileage so they should be just

fine. The drive is similar to what I used in # 14. The two gear boxes

are tied together with a length of 4mm Allen wrench which is a perfect

fix for the hex shaped holes in the gearboxes. The frame was machined

from 1/4" brass bar stock and assembled with flat socket head cap

screws. The cylinder assembly was done similar to # 14 as well only in

this case I used Delrin instead of aluminum. The cylinders were turned

on a lathe and attached the center section. The cross head guides are

made from hollow square tubing with a short length of brass rod that

just fits inside the square tubing and is silver soldered in place. This

then fits into holes drilled in the face of the cylinder. The main rod

is from a Bachmann Annie that was beefed up by adding some styrene to

the top and bottom edges of the rod. The cross head guide was machined

from brass. The motor is a standard Pittman motor and drives the main

shaft through a timing belt. I get some additional gear reduction this

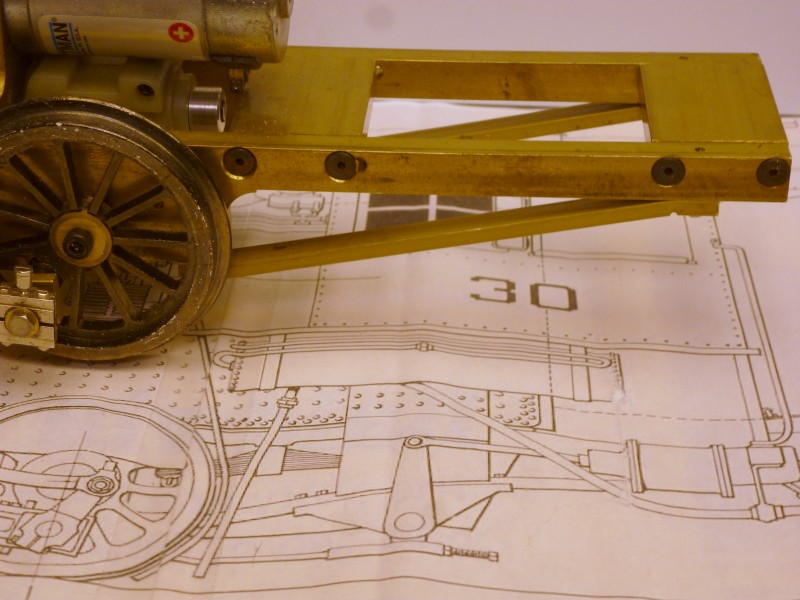

way and it provides a smooth quite drive. The frame is sitting on full

size (1/24 scale) drawing of # 29's sister engine # 30 which was

identical except for the valve gear.

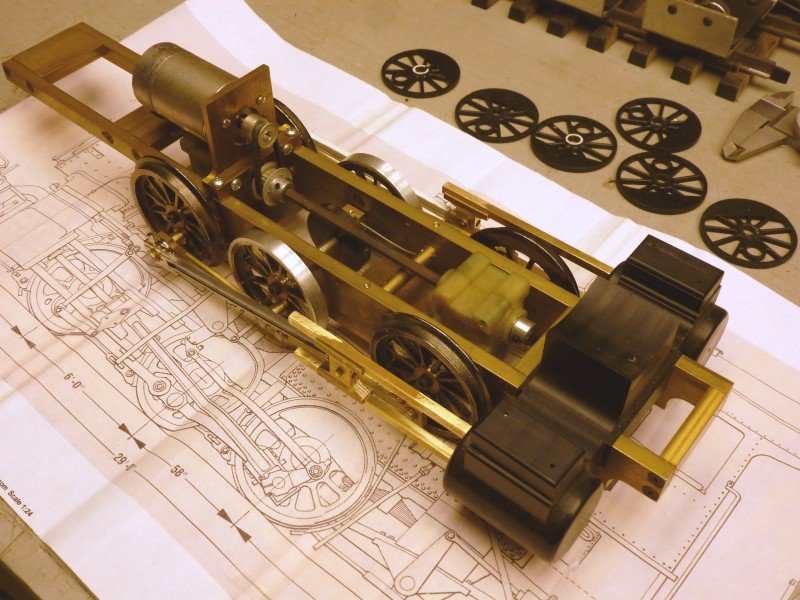

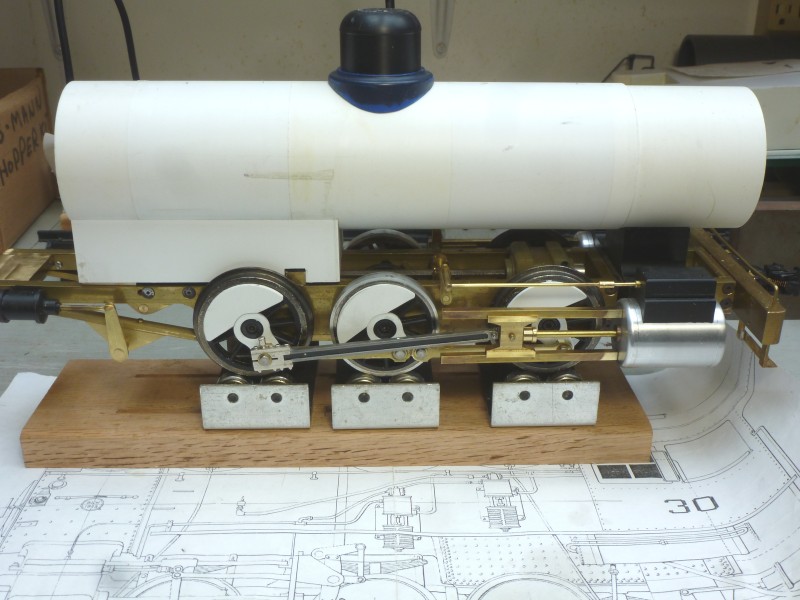

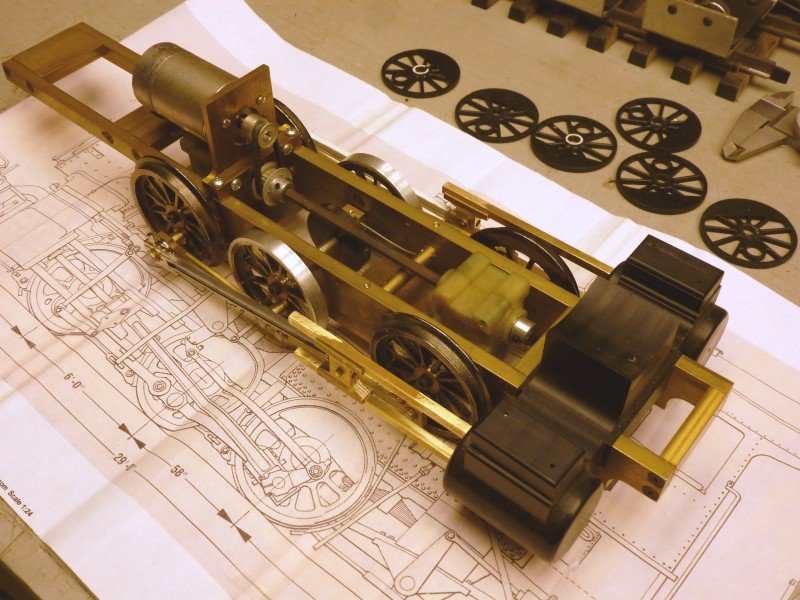

The

next photo shows a different angle. It shows the bearings for the center

axle which ride in a slot in the frame and the method I used for spring

the center driver. The round shaft between the center axle and that

front gearbox has holes drilled in it for a pieces of piano wire which

is held in place by a set screw. This wire extends back and fits into a

hole in the bearing block for the center axle, By rotating the round

shaft one can adjust the amount of spring tension on the axle. Once set

the round shaft can be tightened in place by set screws in the frame.

The shaft has a hole in it that is used to turn it to adjust the

tension. The driver centers shown behind the locomotive have had new

counter weights scaled from the drawing over laid on the original

weights.

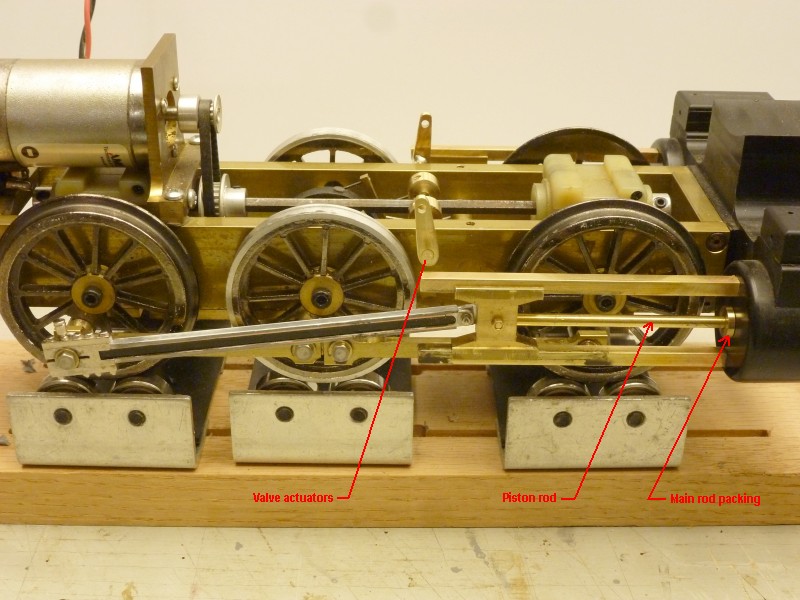

Between

the photo above and the one below several items have been added as

indicated by the red arrows. While I had no intention of duplicating the

complete Stephenson valve gear I did desire a way to add motion to the

valve actuators, something that is seldom done even in large scale.

The

next photo shows how this was accomplished. Two eccentrics were turned

from Delrin and press fit on to the center axle. The eccentrics have a

groove cut into the circumference and two very simple cam followers were

made from brass bar stock and piano wire. The wire rides in the slots

and their up and down motion is transferred to the valve actuator shafts

by yet another piece of piano wire. All of this needed to take into

consideration that the center axle can move up and down. The larger

diameter disk has magnets mounted in it to provide chuff triggers.

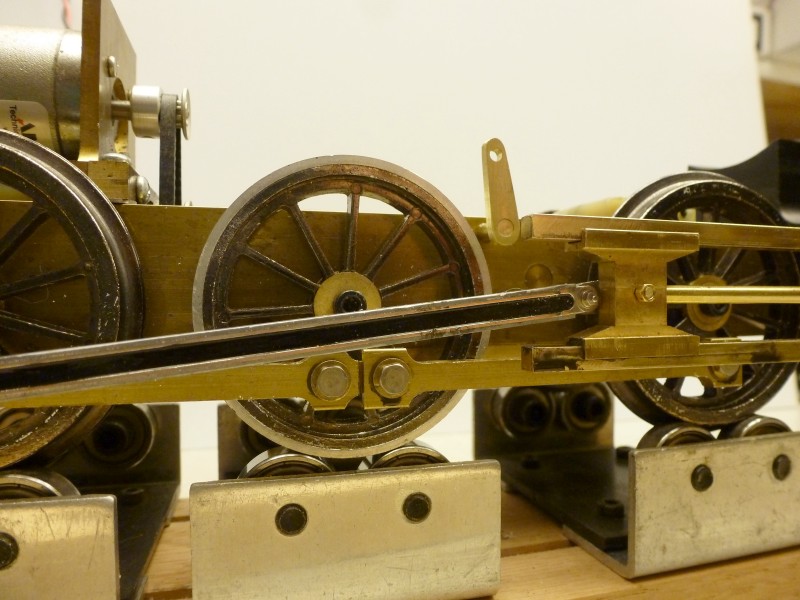

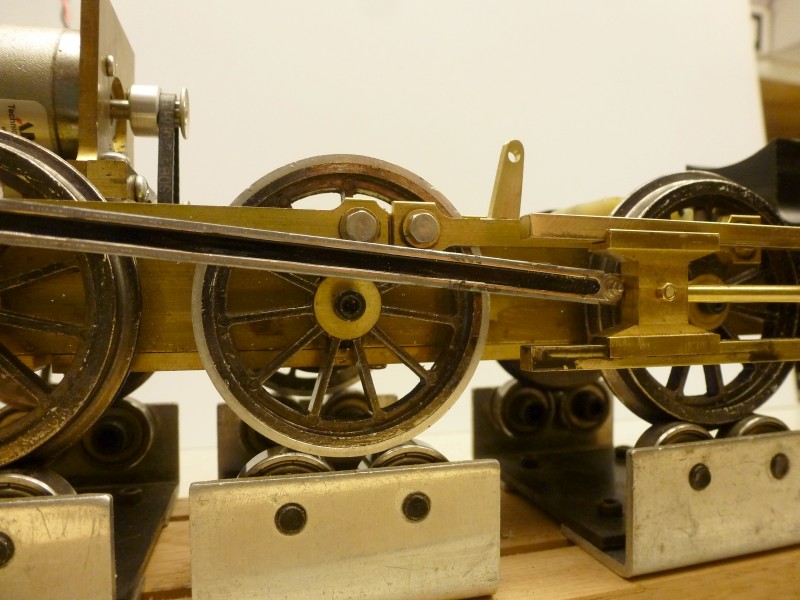

The

next two photos illustrate the range of motion of the valve actuators.

In reality not all that much but enough to provide some interest.

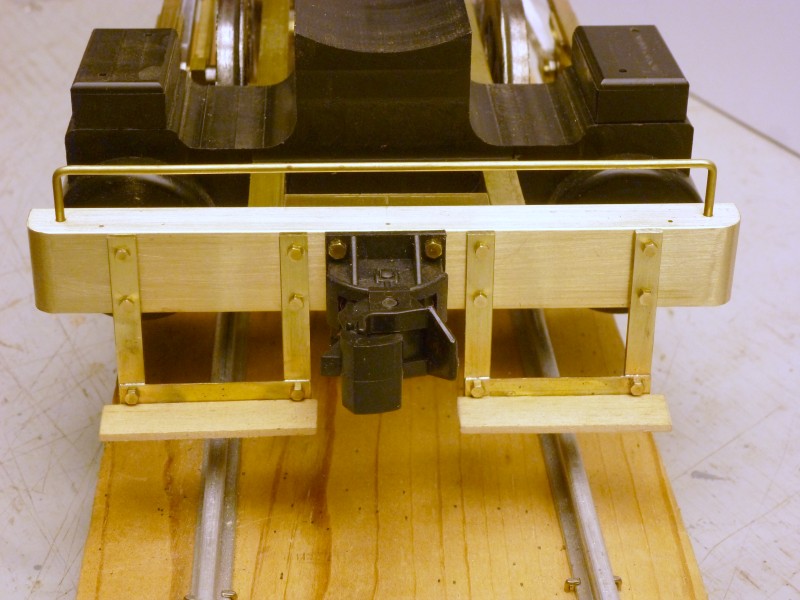

The

next thing that was added was the pilot with coupler. The pilot is all

made from brass and uses actual hex head fasteners. The foot boards are

wood.

The

most current progress on the locomotive is making a template for the

mounting plate that supports the back of the cross head guides. It still

needs some additional shaping at the time of the photo.

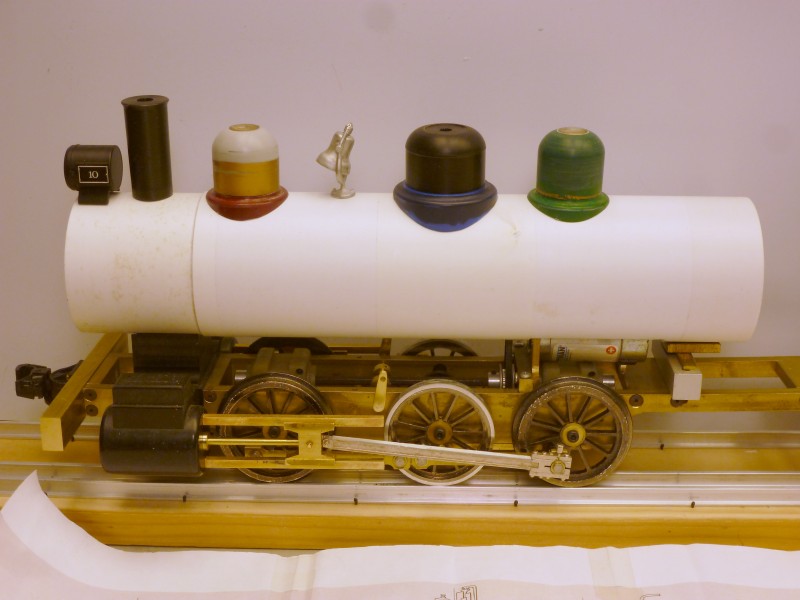

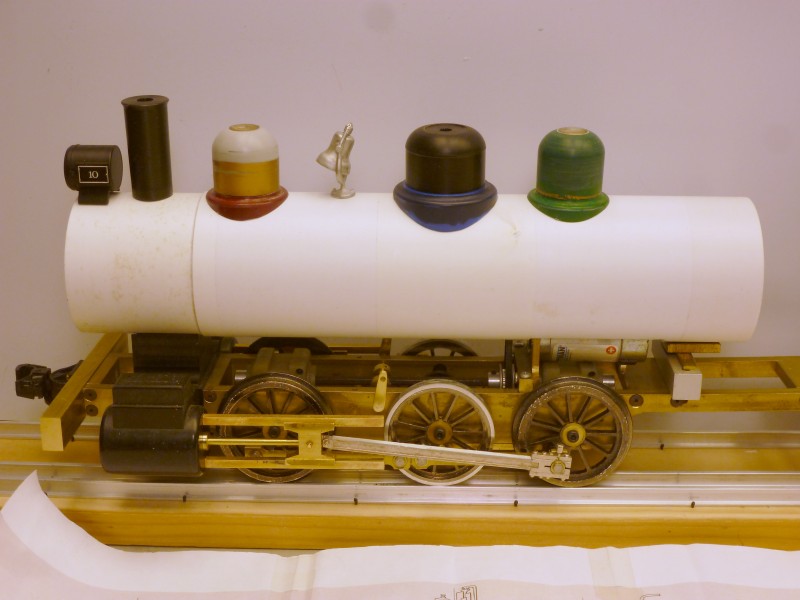

Some

basic work has begun on the boiler. The boiler is made from several PVC

pipe couplers glued together with short lengths of pipe then turned on

the lathe to level it all out and achieve the desired diameter. This was

done as the diameter I needed fell between common pipe sizes. The smoke

box will get a thin styrene overlay with rivets embossed on it. The

headlight is a stock Bachmann item, the smoke stack which still needs a

base was turned on the lathe as none of the available ones I had were

the correct diameter, shape and length. The domes are reshaped Bachmann

items. The large steam dome was turned from Delrin but the base came

from a Bachmann dome. The bell is an Ozark casting. The rear support for

the boiler is just a few pieces stacked to hold the boiler level for the

photo.

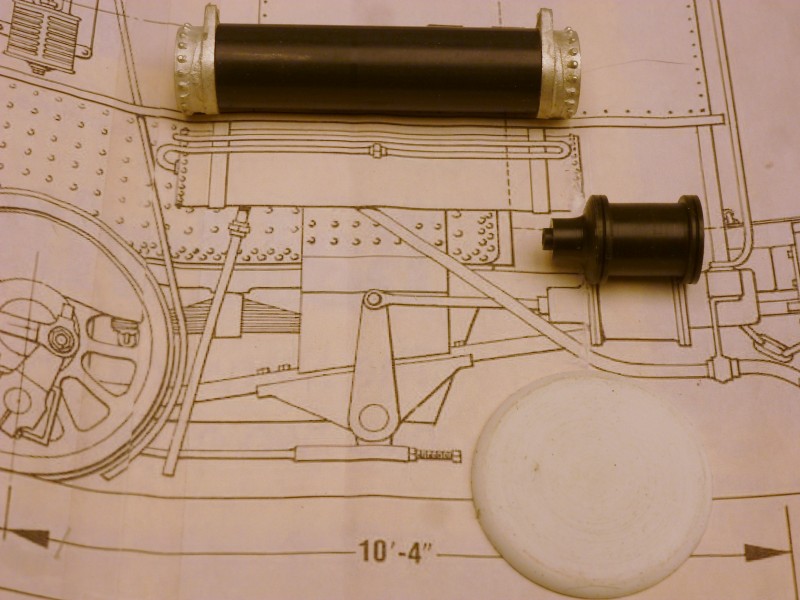

Additional

detail parts have been made. The air tank uses Ozark ends on a turned

piece of Delrin and the brake cylinder is a one piece lathe turning from

Delrin. At the bottom of the photo is a smoke box front made from the

end of a PVC pipe cap.

The

last bit of the frame has been added in the next photo. That's where

progress on the locomotive stands as of the posted update date below.

This

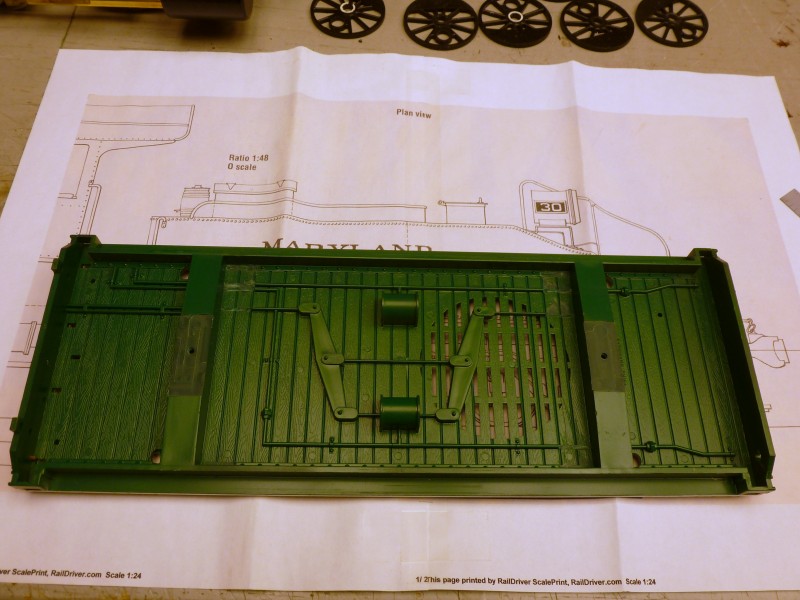

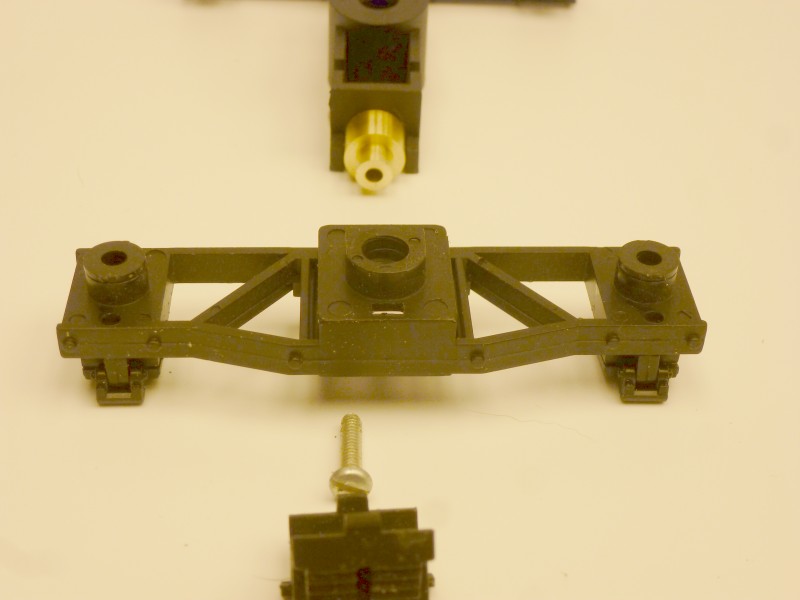

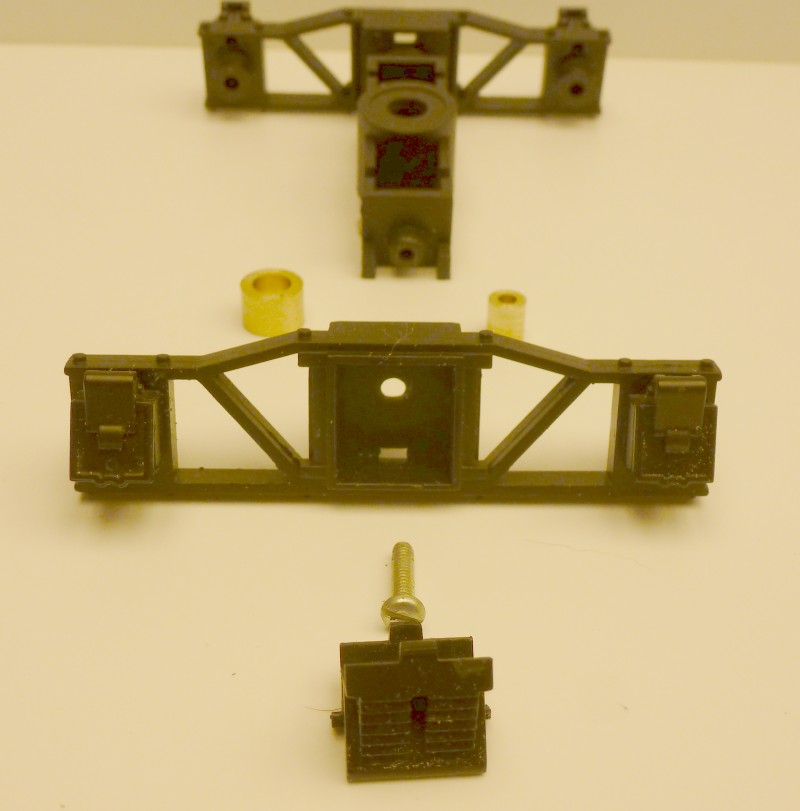

locomotive also needs a tender. Starting with the frame I found that a

Bachmann Annie tender frame was almost dead on for length as shown in

the next photo. It was clamped in the mill vice and all of the various

protrusions that would be in the way were milled flush with the floor.

The

bolsters needed to be re-positioned so any detail that was in the area

where the bolsters needed to be was also milled away.

After

that the old bolsters were milled away, new ones salvaged from an old

car under frame were glued into the new positions.

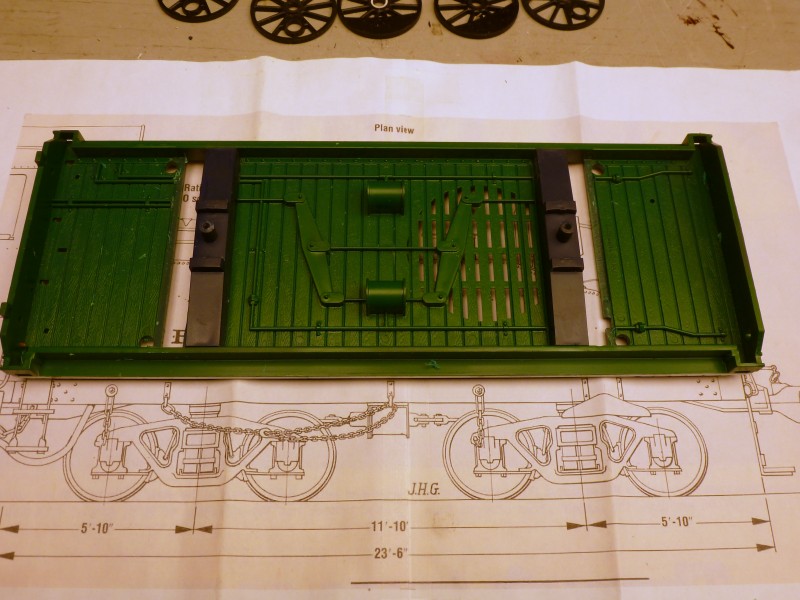

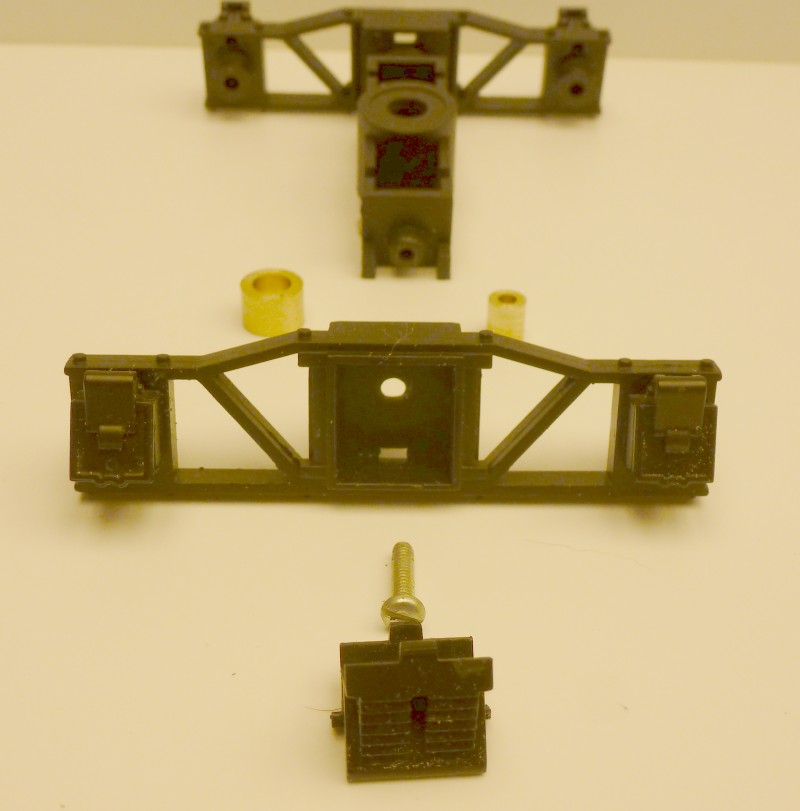

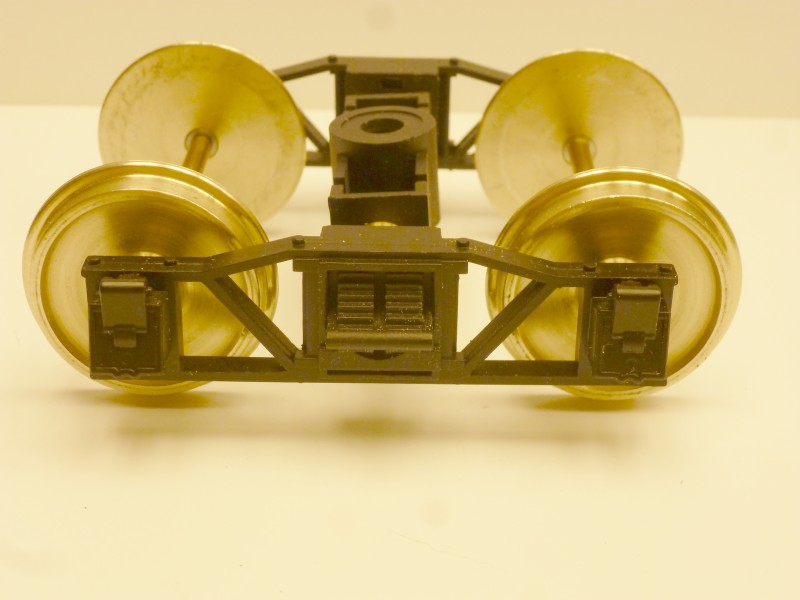

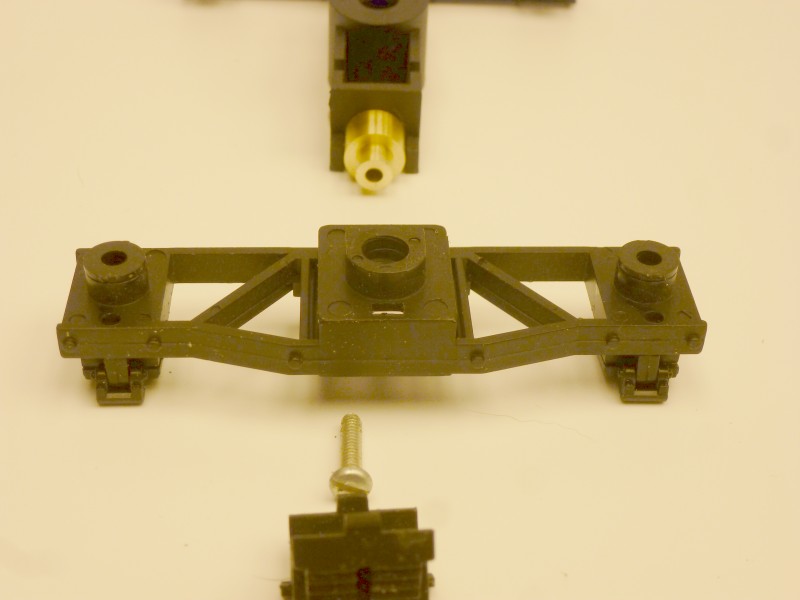

One

of the potential issues I faced was trucks. I needed a truck with a 56"

wheelbase and most of the trucks available were too short in that

dimension. Fortunately another modeler had a set of tender trucks from

one of the 1/20.3 K series locomotives that had the correct wheelbase

for 1/24 and was willing to part with them for a reasonable price. The

only thing I needed to do to them was lengthen the bolster to widen the

gauge. This was done with a couple of turned brass spacers as shown in

the photos below. I had to tap the original bolster screw hole for a

longer and non metric screw. The modification has the benefit of

providing some equalization.

The

wheels came from Northwest Shortline. They were sized to be used as

replacement 42" wheels in 1/29 scale which works out to 33" in 1/24. I

had purchased a lot of these for use on 1/24 scale standard gauge cars.

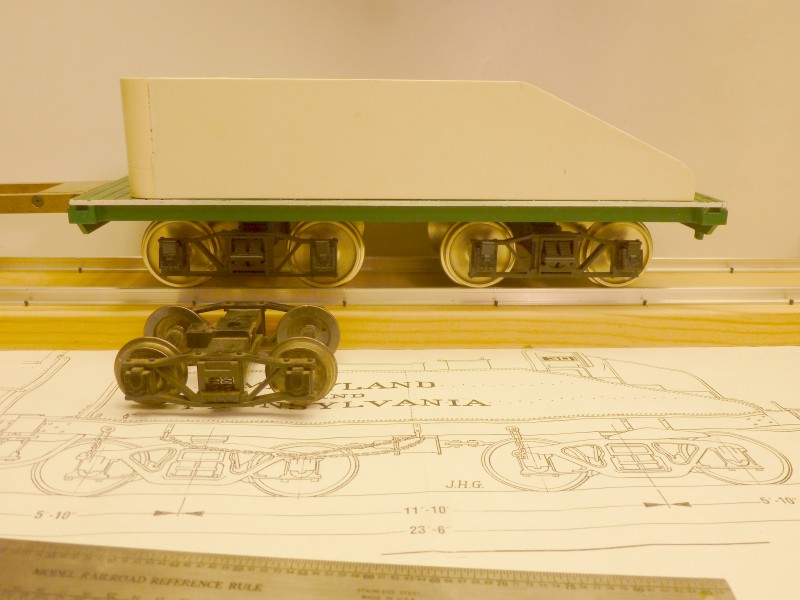

The photo below shows the reassembled truck with the new wheels.

Unfortunately NWSL has recently announced they are closing so unless

someone buys the company and continues the line these will no longer be

available.

The

next photo shows them mounted under the tender with one of my standard

narrow gauge trucks for reference. While the drawing shows Bettendorf

style trucks, photos, including the one at the top of this page, show #

29 came with archbars.

The

tender shell was built up from .062" thick styrene. The front of the

water legs were made from PVC pipe. The bottom of the pipe pieces has

plug that is drilled and tapped to provide a way of securing the front

of the shell to the floor. At the back end a double thickness of acrylic

was shaped to match the back end of the side walls and was drilled and

tapped to provide a way of securing the back of the shell to the floor.

In the next photo the various items that need to be installed in the

shell have been placed to make sure they all fit. The speaker will have

a wooden box placed over it to improve sound quality . The other items

left to right are the battery pack, Revolution receiver and Phoenix

sound board.

A

piece of .020" styrene sheet was cut to fit the top and glued in place.

This is currently where the tender is in the construction process. The

next step will be to sheath it with a layer of thin styrene that has

been embossed with the hundreds of rivets as shown on the drawing. This

process is on hold while I attempt to get my semi automatic rivet

embosser working as is discussed in the article posted on the Articles

Page here.

After

languishing on the shelf for the better part of a year I decided once

the outdoor season was done to get back on this project. While examining

the chassis to figure out what I needed to do next, one of the cross

head guides fell off. When I went to replace it I found what is shown in

the photo below. The delrin surrounding the mounting hole has become

crumbly, almost chalk like. This was the worst one but the other three

were showing similar signs. It appears that the silver solder flux that

I used to solder a piece of solid round stock into the end of the square

cross head guide had reacted with the delrin. While I had cleaned the

area after soldering, apparently some of the flux wicked into the

corners of the square stock and later leached out. I was surprised to

see this as delrin is impervious to most chemicals such as lacquer

thinner, acetone, MEK and alcohol. Oh well, live and learn.

The

only delrin round stock I had on hand was some 2" which would have

required way too much time to turn and way too much wasted stock. I did

however have some 1 1/2" aluminum round stock so the 0-6-0 got a new set

of aluminum cylinders. The new cylinders added about 3 ounces of

addition weight being that much heavier than the delrin cylinders. also

as can be seen the valve actuating rod has been installed

The

most immediate goal is to finish locating all the holes that still need

to drilled in the frame so that it can be disassembled and painted.

First up was mounting the brake cylinders that I had fabricated last

year along with the actuating levers and their mounting brackets.

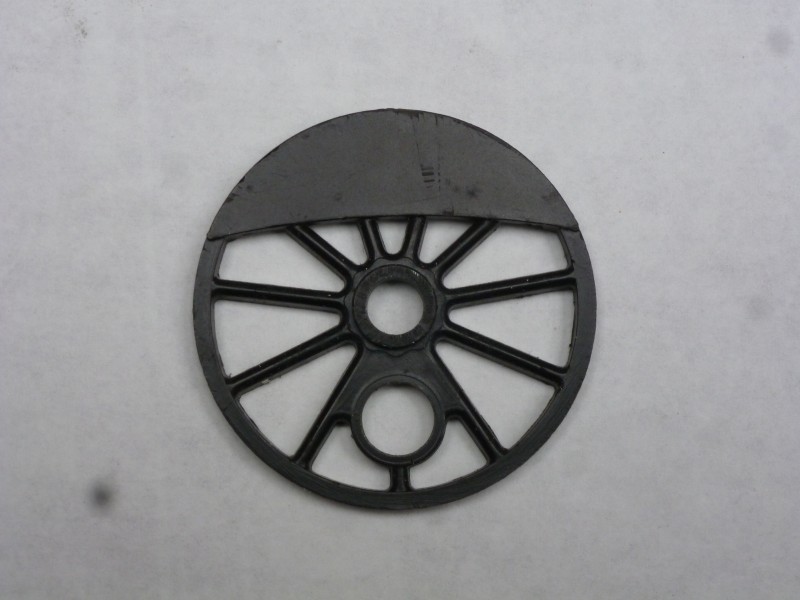

It

was also time to work on the driver center inserts. Below is the

standard Bachmann driver insert. What it needs is new centers and

counter weights to conform to the drawings.

I

didn't photograph each step here but the driver centers started out as a

stack of .060" styrene rectangles cut slightly larger than the final

pieces needed to be. These were held together for machining with pieces

of double sided tape. The stack was then place in the vice on the mill

and the two holes drilled out, starting small and working up to the

final size.

The ends were then rounded using a fixture

like the one below. The plate was set on the table of the belt and

advanced into the belt until the metal touched then it was clamped and the

stack rotated back and forth a little at a time to prevent melting until

the end was rounded. Both ends were done the same way

The

counter weights were made by cutting a circle of .060" styrene. I could

get two weights from one circle and all other cutting and shaping was

done by hand. In order to determine where the mounting points for the

boiler were to be I needed to add the firebox to the boiler. This again

was made from .060" styrene which was set into grooves milled into the

boiler and glued. The entire boiler will be covered with a thin veneer

of styrene at a later time to facilitate adding rivets. The following

two photos show progress to date. The boiler will be removed once

mounting holes have been located and drilled so that more work on it can

be done. I still need to mount brake hangers and fabricate and install

the leaf spring assemblies before the frame can be painted.