Signals

What's that you say, signals on

a small narrow gauge line ? Well, while to my knowledge no automated

signalling was ever done on any American narrow gauge railroads, it

certainly could have. Low labor costs back in the day would have made it

less expensive to use manned posts to control trains than to invest in a

signalling system but it's my railroad and I decided I wanted some

minimal signalling. I have always been fascinated by semaphore signals

and when I saw Indiana Signal Systems semaphore signals I was hooked.

The

first application I had was for a signal to be located at the departure

end of the yard to let the train crews know when they were clear to

leave the yard and enter the mainline. This would be mostly for

appearance but when and if operations are staged it would provide a

method of spacing out locals as they leave the yard. The signal would

remain in the green position until such time as a train left the yard.

On it's way out it would trigger the signal to change to a red

indication and hold for some period of time before transitioning back to

green. The first semaphore I bought was set up to use photo sensors to

detect the passing train and change position and hold for an amount of

time determined by some DIP switches mounted in the control box portion

of the signal. I was dubious about how well this would work based

on my experience with these types of sensors used on industrial

machinery. Even in an indoor application various reflections and

lighting conditions can cause problems and I felt it would be even worse

outside with the effects of the sun. Turns out I was correct in my

assumptions as I had little luck getting the signal to work with any

degree of reliability. After conversing with the manufacturer it was

determined that the signal had an issue and was returned for repair.

When I got it back it did work better but I still wasn't happy with it

and after further conversation with manufacturer I was provided with the

information needed to modify the circuit so I could trigger the signal

using a track side switch. Locomotives would have magnets installed to

activate a reed switch located between the ties and trigger the

signal. This was implemented and worked quite well and the magnets

would be needed for other functions later on.

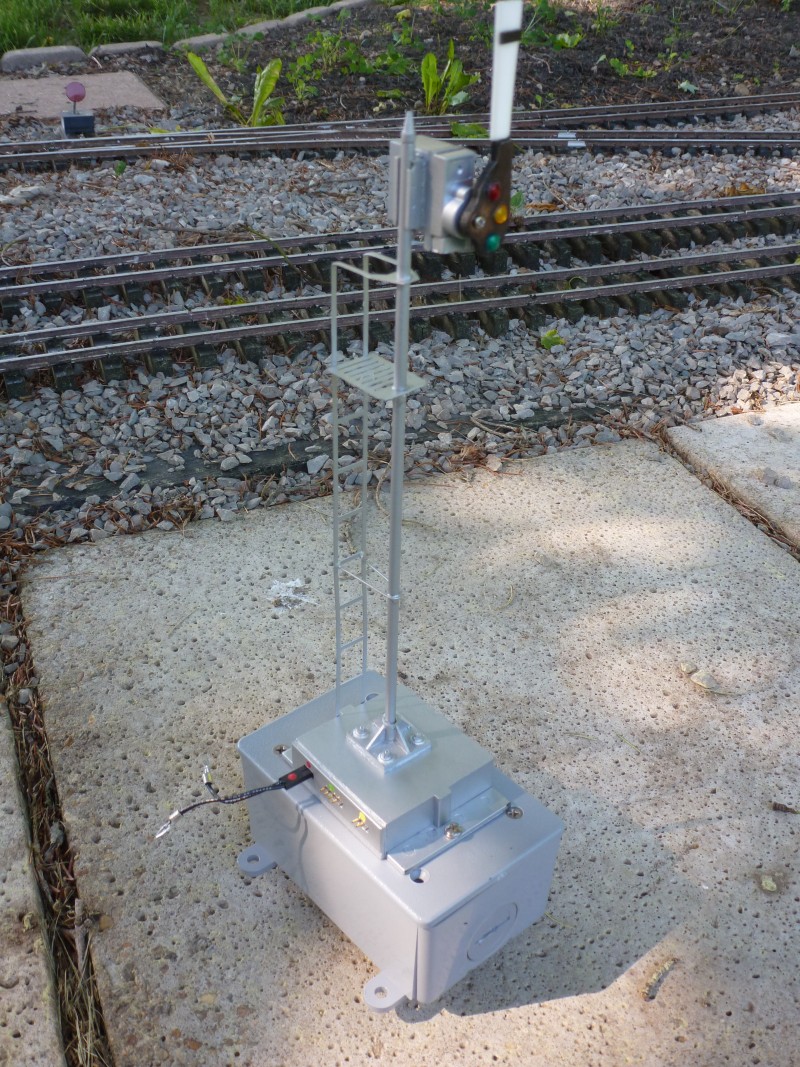

The

signals themselves are not weather proof so they could not be left out

all the time. A method would be needed to allow them to put away when

not in use. I ended up using weather proof plastic electrical boxes to

protect the electrical wiring and connectors and mounted the signals to

the lid of the box. When not being used the screws holding the lid on

are removed and a blank lid is installed in its place. The box is sunk

into the ground up to the lid. The multi conductor cable which brings

power in and connects to the under track switch enters through holes

drilled in the side of the box which are sized for a snug fit and sealed

with silicon caulk.

The

photo below shows the first signal purchased mounted to an electrical

box. The two holes in the side of the control base were for the photo

sensors and the one on the front was for access to the on-off switch. As

it came from the manufacturer it could be powered by a battery or

external power.