RC&G # 7

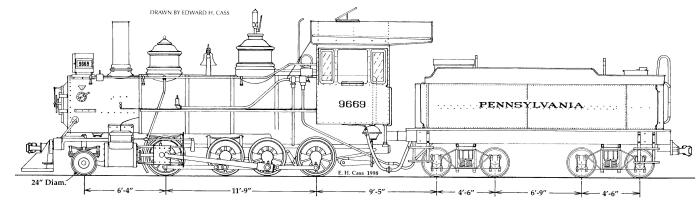

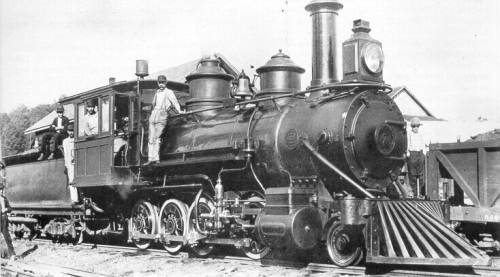

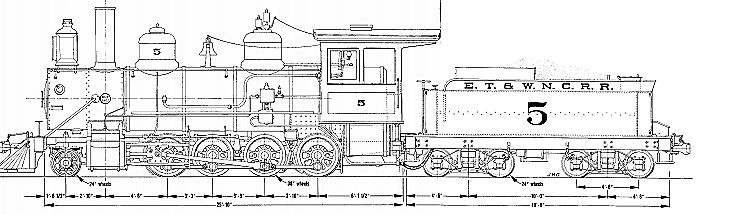

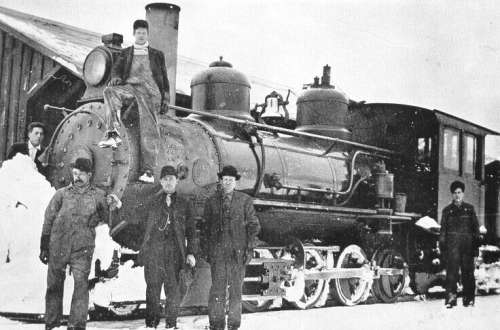

Both the EBT and the ET&WNC operated small Baldwin 2-8-0's. Both of these engines were just slightly larger and had different wheel spacings than the C-16's built for the D&RGW. The EBT engines were in fact built to the same plan as the C-19's. Baldwin built hundreds of engines with this wheel arrangement with a variety details. Not wishing to start from scratch, I decided to modify Aristo's C-16 to create a generic Baldwin for the RC&G. As can be seen in the two plans below, both of the prototype engines had much longer smoke boxes than the C-16 and the main rods were attached at the third rather than the second as on the C-16. I have incorporate both of these features on my version. The RC&G version will look more like ET&WCN's #5, with smooth unfluted domes, but will have a steam generator and electric head light. The boiler will be smaller in diameter than #5 but the boiler height at the top of the boiler will be close to matching the prototype's height due to Aristo's infamous 1/4" that they added to the C-16, supposedly to compensate for the drive train. I did lower the cylinders and pilot on mine but left the boiler alone.

This plan shows EBT #7 after it was sold to the Ohio River & Western which was later purchased by the Pennsylvania. The engine as built for the EBT was made to the same diagram as the D&RGW C-19's. EBT had replaced the original wooden cab with a larger steel cab after the original was destroyed in a fire. The OR&W added the electric headlight and generator and a larger homemade tender. EBT's # 7 was built in 1881 and was Baldwin's construction # 5677. The photo below shows how the engine looked in service on the EBT prior to the fire which destroyed the original wooden cab.

ET&WCN's # 5 was built in 1903, was Baldwin's construction # 21893. The photo below is of sister engine # 6 while in service on the ET&WCN.

The picture below is the stock Aristo C-16.

The major changes I made to the Aristo unit are:

1. Lowered the cylinders to the center line of the drivers.

2. Extended the main rods to the third driver.

3. Lengthened the smokebox

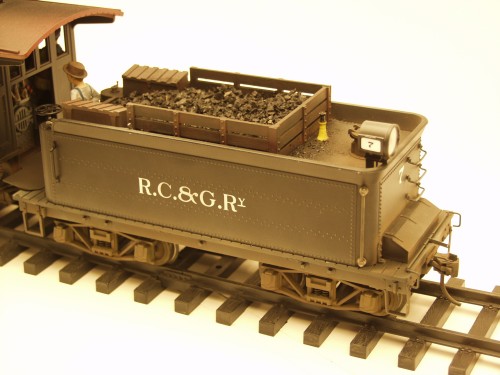

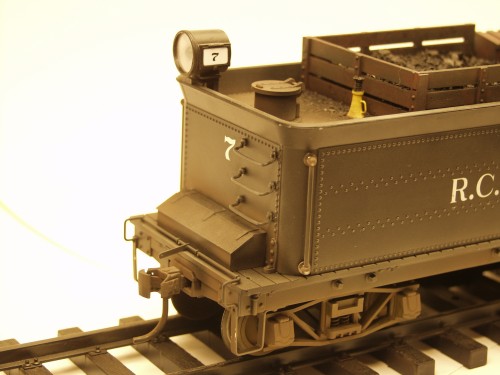

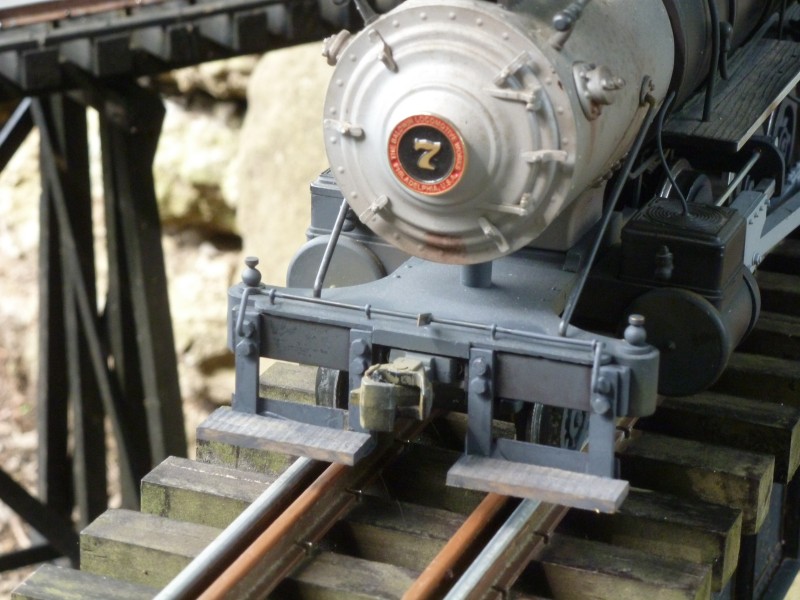

4. Replaced the dual air pumps with a single brass cast unit, replaced the whistle and pop valves with Ozark parts, added air tanks under the cab and replaced the air tank mounted on the tender with a tool box, modified the headlight to remove the angled number boards, added smokebox cleanouts (Ozark) added smokebox dogs to front of smokebox and replaced the number plate with a tie tack sold by the Friends of the EBT. A cab vent hatch was added to the cab roof as well as some rain deflectors to the cab roof lower edges.Inside the cab I added a throttle, lubricant shelf over the firebox door and injectors. The tender also got some grab irons on the back of the tank and stirrups on the back beam to allow the fireman access to the water hatch without climbing over the coal load, uncoupling levers and a backup light was added as well.

5. Replaced the solid leading truck wheels with spoked wheels.

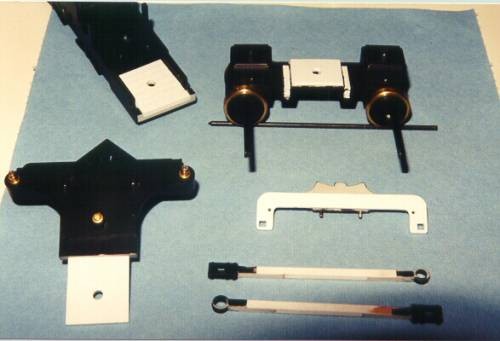

The photo below shows parts that modified to lower the cylinders, pilot and the main rod extension.

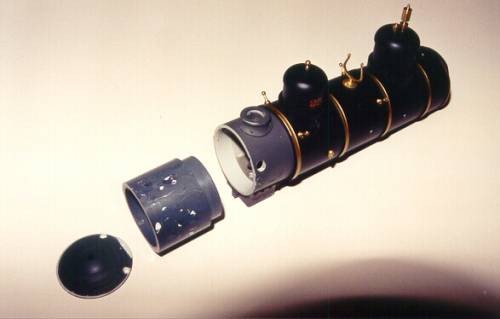

The next photo show the turned piece of schedule 80 PVC pipe used for the smokebox extension.

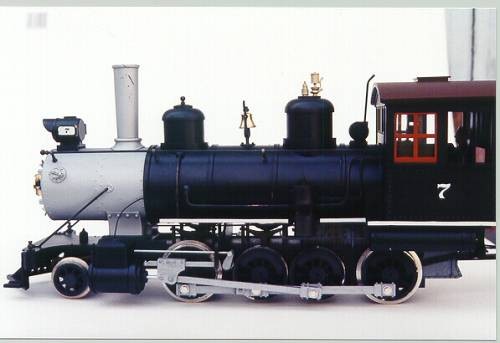

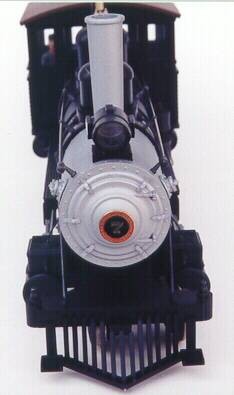

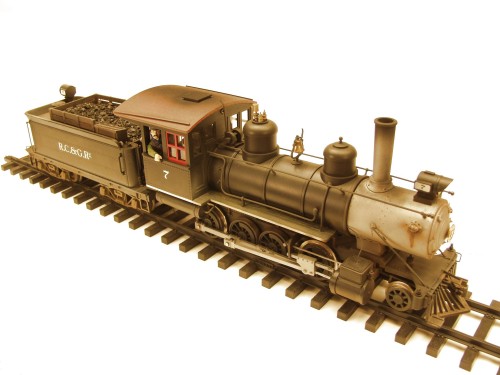

The next three photo's show the engine after reassembly and painting and prior to weathering.

All in all, I was quite pleased with the end result. The Aristo engine had some quality problems right out of the box, both were easy to fix but one was tough to find and required dismantling the entire drive mechanism to find and fix. The first one I noticed was a bind in the mechanism which I traced to the piston rod bottoming out in the cylinder on the engineers side. This was fixed by clipping 1/16" off the piston rod. The other problem was a bind that caused the locomotive to lurch primarily when running in reverse. This turned out to be due to having too much slop in the casting that holds the front worm gear inline with axle gear. It manifested itself in reverse due to the torque causing the worm to be misaligned with the axle gear. When going forward the torque pulled the gear back into alignment. This was fixed by installing a shim on the one side which kept the worm in alignment all the time.The following photos show the completed locomotive.

Following the

completion of this around 2007 it was in service for several years. I

found that Aristo's drive that was provided did not have a lot of torque

and it's starting characteristics left a lot to be desired. When Aristo

released an updated version with it's modular gear boxes a few years ago

I bought one and rather than go through the modification process all

over again I stripped out the new frame and drive train and installed it

in this locomotive. It was not as easy as it sounds and did require some

modifications, none of which altered the main features. I also added a

Phoenix sound board at the time. The difference was like night and day.

The starting speed was low and smooth and it had much better running

characteristics. I liked it so well I have acquired a second locomotive

which will be modified similar to this one and will be the operational

sister to this one. These two locomotives will become the standard

locomotives for use on local freights on the line. Since these engines

will be used extensively for switching ops I decided to remove the cow

catcher and install a foot board pilot

When the second locomotive is finished I will post photos here.

Updated 3/2/19