R C & G

20

RC&G

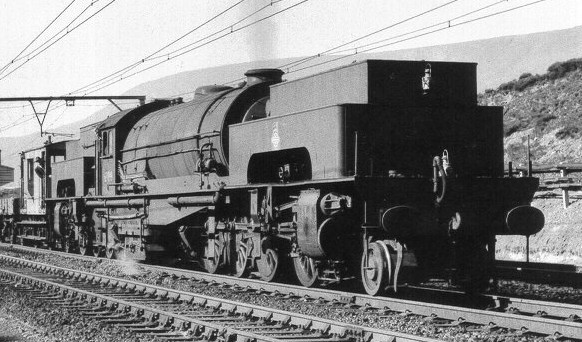

#20 will be a Garratt type locomotive. Foreign looking to most they

were originally designed and built by Beyer & Peacock in Great

Britain and used widely in Europe, Africa and other locations around

the world. The concept was to more equally distribute the

locomotives weight evenly over the drivers and carry all of the

weight of the fuel and water over the drivers and eliminate the

separate tender.. There were other advantage and disadvantages The

largest disadvantage for use in the U.S. was limited range due to

the small amount of water and fuel carried on board. Alco had the

rights to build and sell the design in the U.S. but I doubt they

ever tried very hard to sell them as they would have had to pay a

licensing fee on every one they sold.

For

those not familiar with the design the photo below shows a common

form they often took. Many of the designs had sort of an art deco

look about them with lots of curves and simplified looks.

Water

was carried in the front tank and fuel and water in the one behind the

cab. The engines pivoted where they were attached to the frame. The

design typically used large diameter boilers that were shorter than

those used on many larger American locomotives. Beyer & Peacock felt

that extending the boiler beyond a certain point had diminishing returns

as far as recovering heat from the exhaust gases.

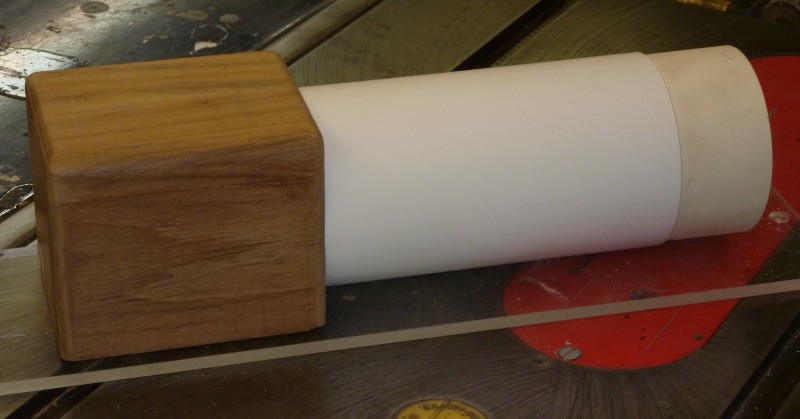

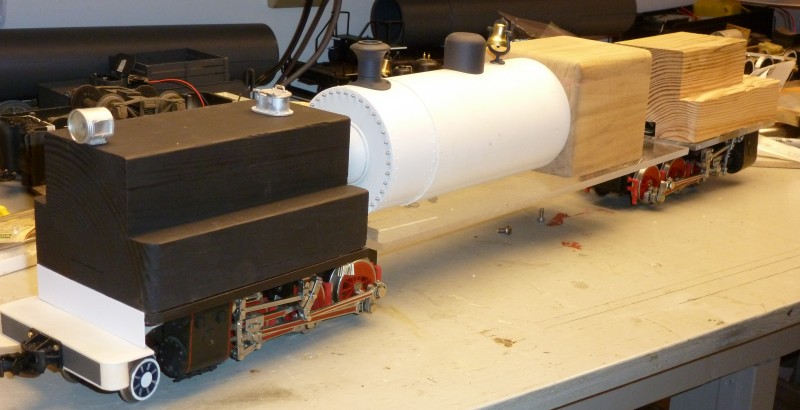

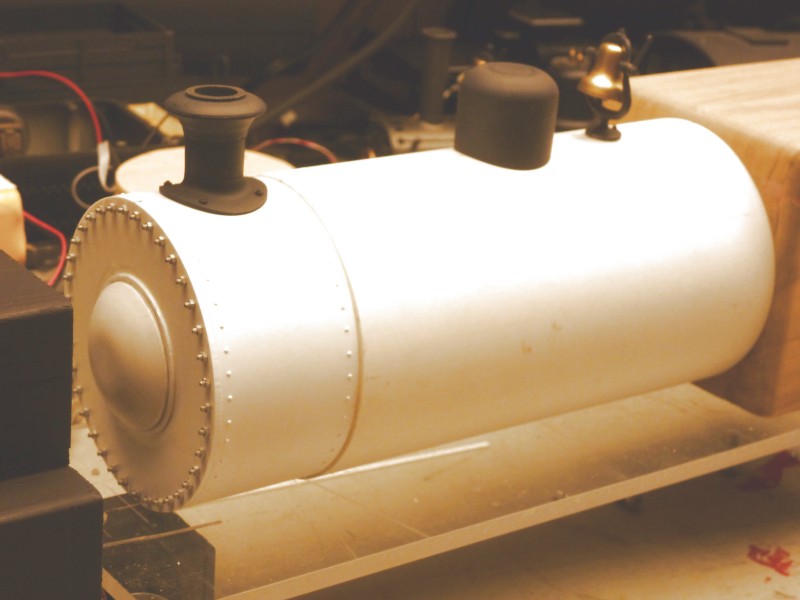

My concoction is going to use the supposition that the RC&G had approached Alco about purchasing a Garratt style locomotive and was put off by the cost and instead purchased a used locomotive and rebuilt it using American appliances and design ideas. I liked the squared off look of the one shown in the next photo. This is a much larger engine but I figured that an Americanized version would be less art deco and more utilitarian.