R C & G

1

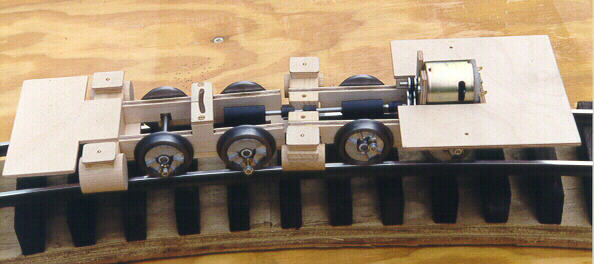

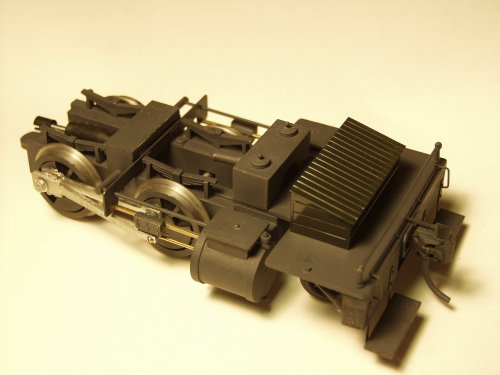

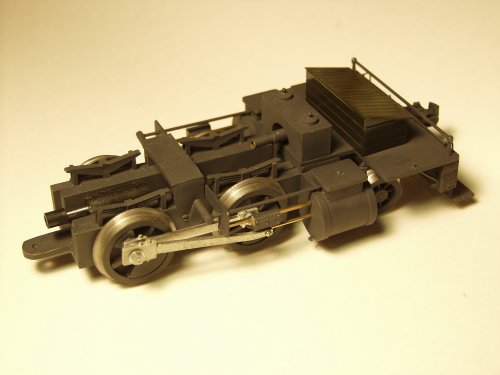

R C & G locomotive # 1 is a freelance design and as such has no prototype. Baldwin built several 2-4-4-2 mallets, but none with saddle tanks and none in narrow gauge. It did build numerous 2-6-6-2T's with a variety of side, split and full saddle tanks and many of these had tenders added in later years. Only two tank type mallets were ever built for narrow gauge use in the United States, those being the famous Uintah locomotives. Baldwin did design a mallet for the E T & W N C but it was never built. My model represents a "could have been" design based on the NENG kit for a 2-4-4-0T. I decided to add a trailing truck prevalent in all Baldwin designs built for logging use and added a tender so as to have a place to put the battery and receiver. The tender comes from the Bachmann 4-6-0 that was shortened. The first photo below shows the frame and drive built out of the box and tested and is ready to be disassembled for painting.

Modifications to stock kit to date include fabricating new front cylinders as the ones in the kit were the same size as the rear ones and replacing the flexible tubing used to couple the two gearboxes with NWSL universals. The kit bearings for the main drive shaft (brass eyelets) were replaced with bronze flange type bearings from NWSL. Some folks have not had much luck with the NENG belt drive which consists of two grooved pulleys and an "O" ring belt providing a 3:1 reduction between the motor and gear boxes, but it appeared to work fine in this application. I could stall the motor with out the belt slipping and the overall ratio of 75:1 seems to provided a nice slow speed.

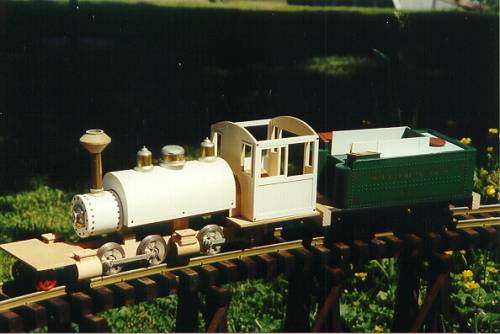

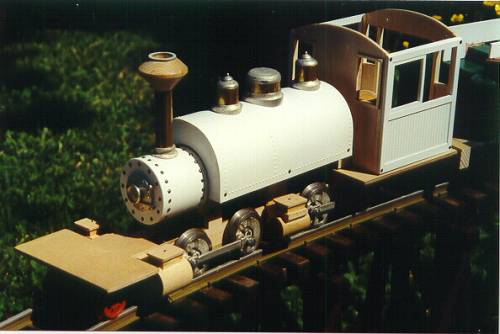

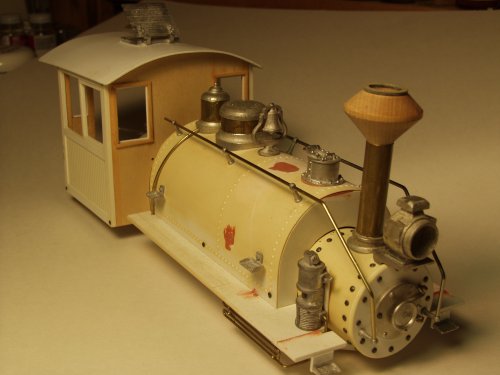

This and the next two shots show the progress to date as of 6/98. Smoke box and saddle tank have been laminated with .020" styrene. The smoke box uses track nails for rivets, the tank has embossed rivets. The cab was modified to eliminate the fuel bunker no longer needed as a result of the tender. I used the kit front and rear cab walls and fabricated new side walls from styrene. Since the cab is shorter there is a short section of the boiler visible between the tank and the cab.

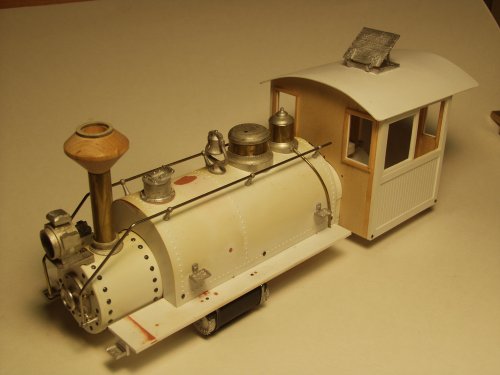

The tender, a standard Bachmann unit was shortened in length and narrowed in width. To hide the seams on the top a new deck was installed and the coal bunker was was built up. The frame was fabricated from wood and Plastruct angle. Bachmann trucks were used with the stock wheels replaced by New Brite spoked wheels with metal treads. This sets the tender a little closer to the rails as the New Brite wheels are smaller in diameter and keeps the tender from overwhelming the locomotive.

This closer view shows that there is still a bit of work to be done, main rods, cross head guides and supports, running boards, piping, air compressor and air tank, head light, pilot beam, cab roof and cab details to name a few. This is where the project stood in early 1999.

The next bit of progress occurred during 2002. As shown in the series of photos below. The first one shows the front engine after it was disassembled, painted, re assembled and detailed. The new larger front cylinders were added as was a sand box and tool box on the front pilot. A pilot beam with foot boards, coupler hand rail and uncoupling levers. The cross head and main rods installed as well as the faux valve gear and drifting valves. All in all I was quite pleased appearance wise at this point

Updated 2/27/19