Illuminated Marker Lamps

I always liked the idea of

illuminated marker lamps on cabooses and other pieces of rolling stock

but never cared for the way various manufacturers have done this over

the years. The markers either look way oversized for the scale or have

rather ugly and oversized wires connecting them to the car or both. I

have used Ozark Miniatures cast white metal marker lamps on cars for

years and they have a nice scale appearance and are molded hollow so

that they could be illuminated but using an incandescent lamp would

require using external wires to connect them ruining the idea that back

in the day these were lit buy kerosene. Through hole type LEDs could

also be used but again the wiring issues rears its head. At some point I

thought about using surface mount LEDs but how to diffuse the light from

one of these as they tend to be very directional. It was then I hit on

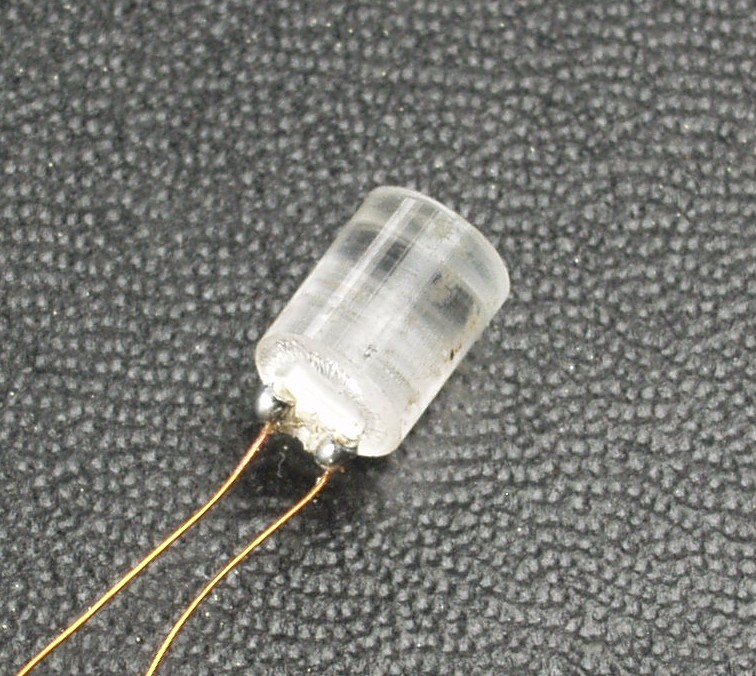

the idea of turning a piece of clear plastic down to fit inside the lamp

casting and gluing the LED to the bottom of the plastic with the

emitting side facing up towards the plastic. Seemed like it could work

but what about the wiring. Well LEDs are very low current devices so the

wire could be really small. I settled on some # 60 gauge magnet wire.

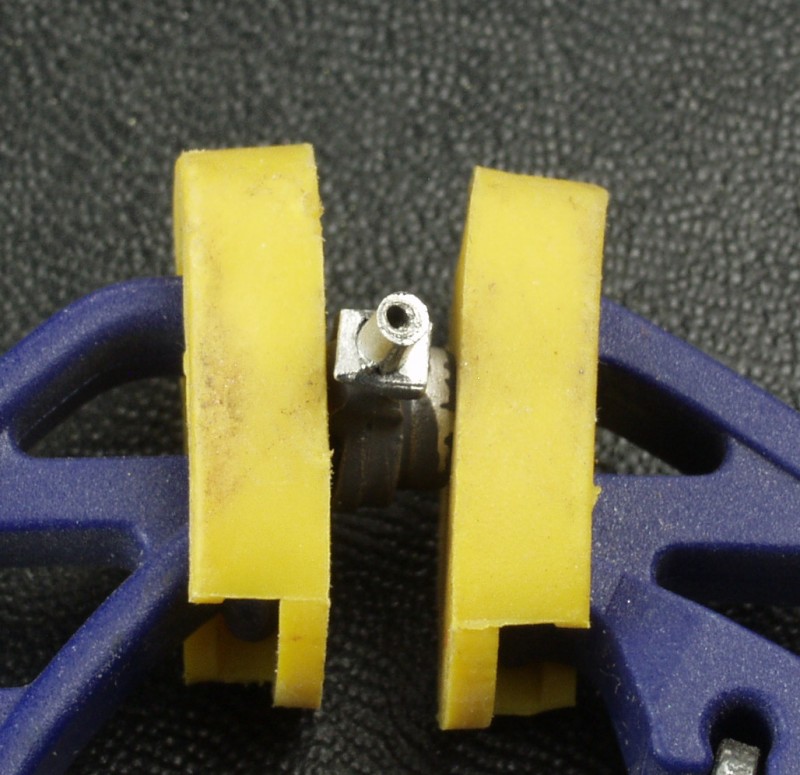

This was small enough in diameter that I could thread it through the

mounting bracket assuming I could drill a hole through it. So I acquired

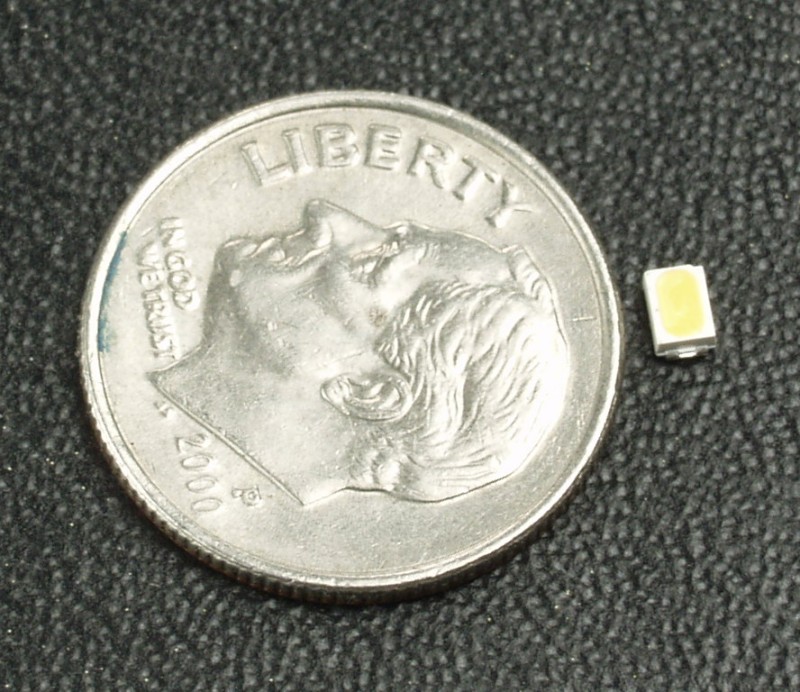

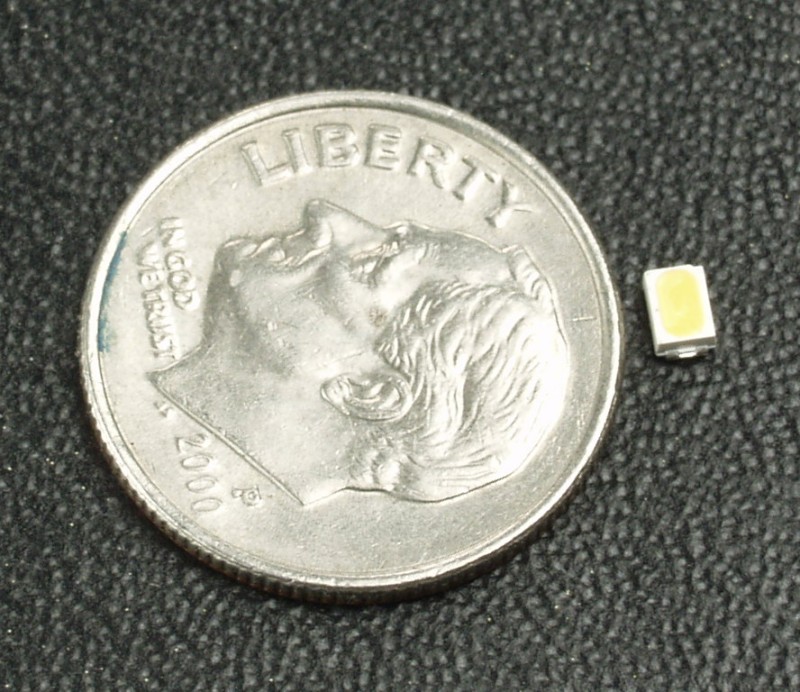

some surface mount LEDs in a warm white color. These I believe were 1206

size (.012" x .008") and as you can see below are quite small.