Automatic Control of Loop Switches

While the RC&G is designed

to provide plenty of opportunities for operations I wanted it to be

capable of running continuously for guests or times when I just want to

kick back with an adult beverage and watch it run. To that end the

layout functions as a loop to loop design and for it to be used in a

continuous running mode some method of operating the loop switches at

each end automatically.

Some

folks just use spring operated switches by my experiments with them were

less than satisfactory and I also wanted to be able to manually operate

them when doing operations so I decided to go a different route. Since

locomotives would be equipped with magnets to operate the signal system

I decided to use them to control the loop switches as well.

The

loop switches are operated by air cylinders and when not activated they

hold the switch points in the position for normal flow. In what I call

the automatic mode, when the locomotive completes the circuit of the

loop and is approaching the switch, its magnet will activate a reed

switch mounted under the rails. This in turn will activate a time delay

relay which applies power to an air solenoid valve which supplies air to

the air cylinder and throws the switch to the position needed. This uses

the same time delay relay as used in the signal system which is

described in another article. The relay holds the switch in the new

position long enough for the train to pass then returns to the default

position. The time is adjustable and is nominally set to 90 seconds

which is more than adequate for the train lengths and speed I use.

That's

all well and good for the automatic mode but I also needed other options

for use during operations. The two I selected are a manual mode which is

controlled by an electrical toggle switch located near the loop switch

and a radio control mode. The Revolution system I use to radio control

my locomotives also as accessory boards which can be controlled by the

hand held transmitter. By using one of these boards to activate the air

solenoid radio control can be achieved.

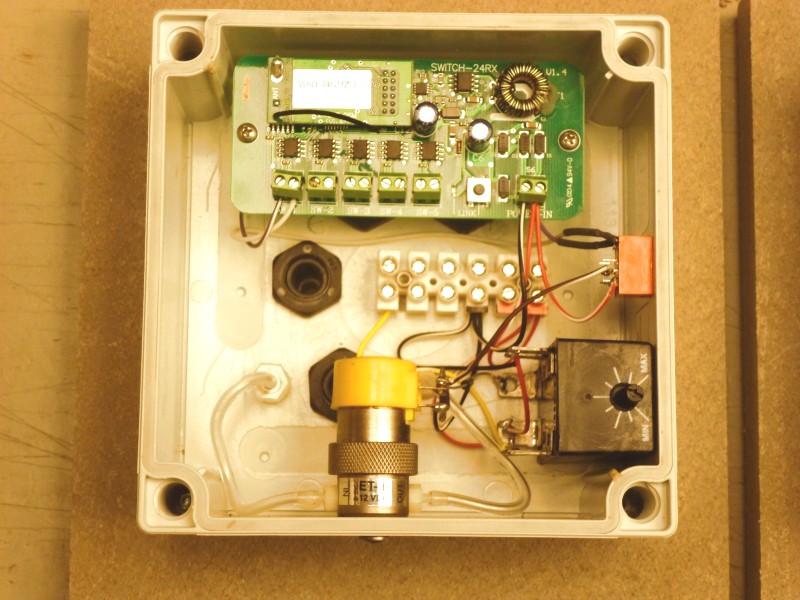

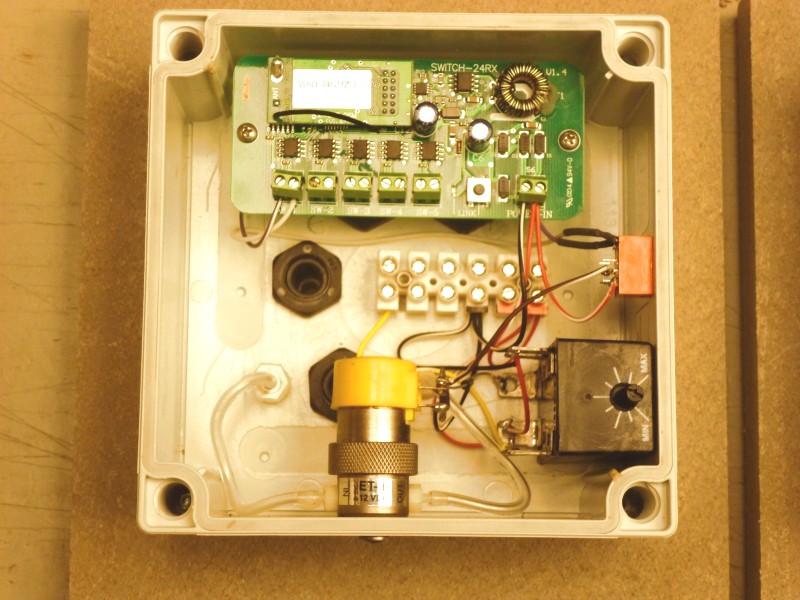

OK,

I had a plan but I needed somewhere close to the loop switches to

install this stuff that would be weather proof. I decided to put the

circuitry in a weather proof plastic electrical junction box. The next

photo shows the parts installed and wired up. The Revolution accessory

board is at the top, the air solenoid valve bottom center, the time

delay relay bottom right. The orange device mounted right center is a

small DC relay. This is activated by the accessory board and in turn

activates the solenoid valve. I wasn't certain that the accessory board

could handle the current required by the solenoid valve so this was

added as a safety feature. One other task this box would handle is that

of a junction box for the 12V circuit that is routed around the layout

for lighting and other devices like this. The terminal strip not only

provides tie points for the internal parts but will terminate the 12V DC

in and out lines.