Coal Cleaning Plant

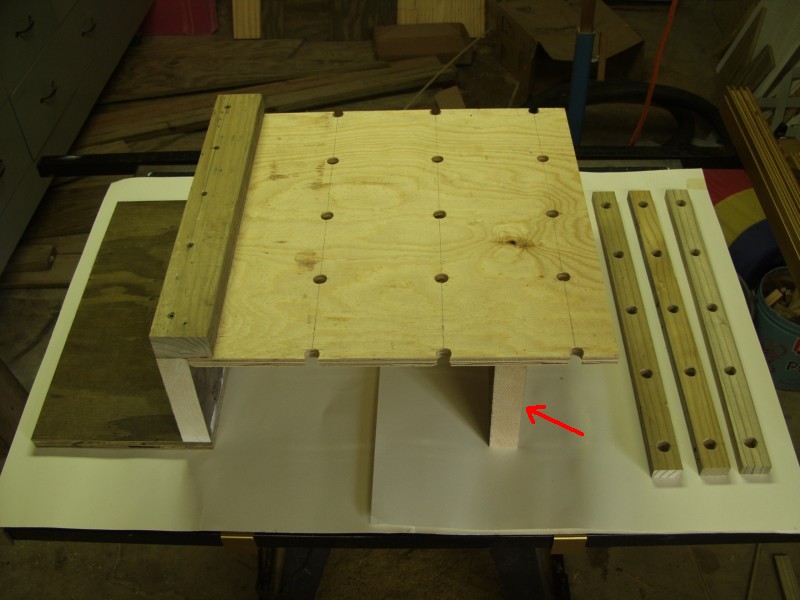

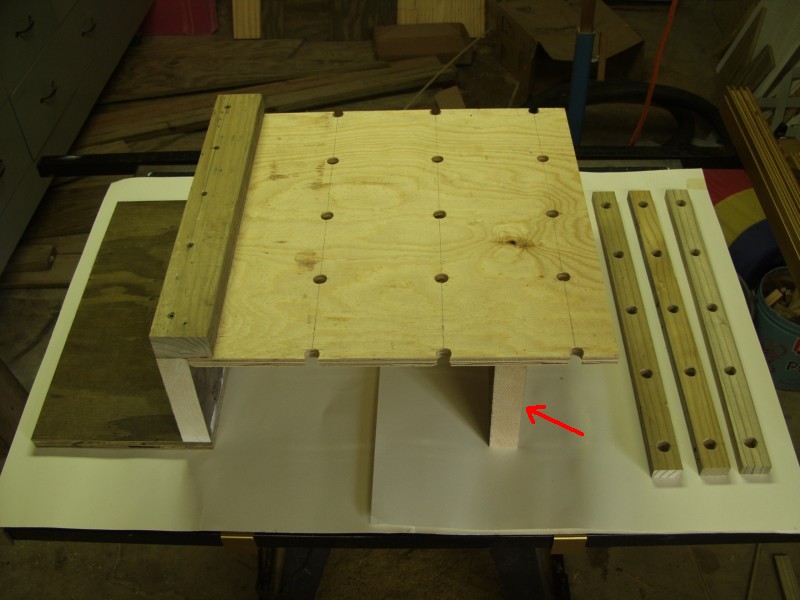

This will be mostly a photo

article as the photos are pretty well self explanatory. The base for the

structure was made from PT lumber of various sizes, the large base

section with holes is normal exterior grade plywood. It will be raised

off the ground, completely covered on the top and painted on the bottom

so I'm not concerned about rot on it. To the right are pieces with

holes, these will be the bases for the 'H' columns which will support

the large upper section when complete. The piece that the red arrow is

pointing to is just a temporary support.

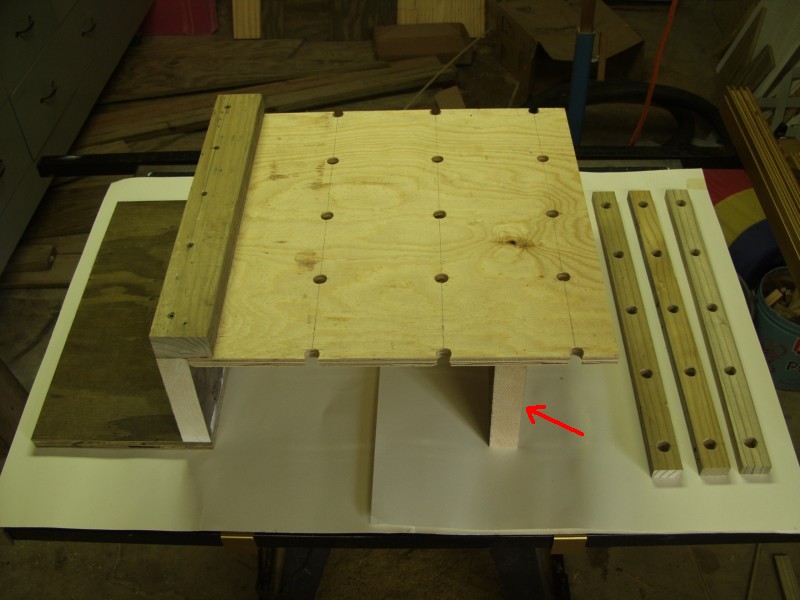

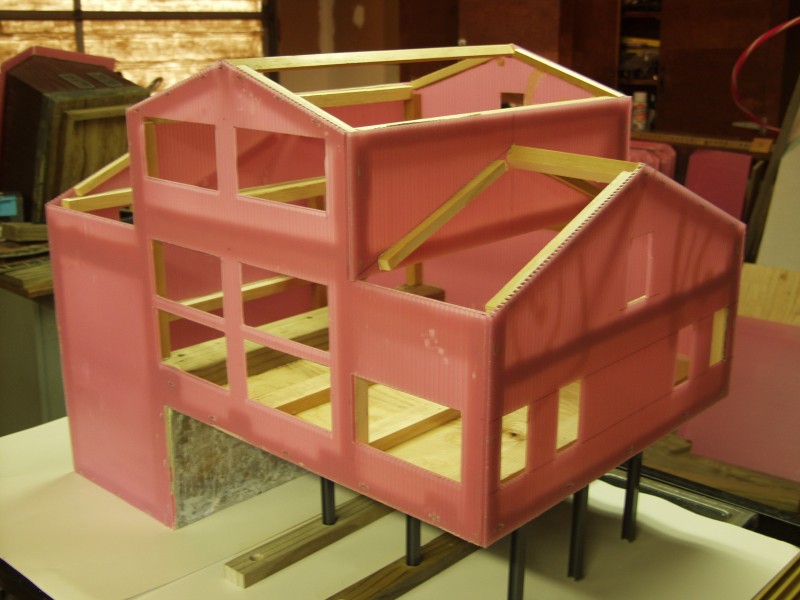

The

next photo shows a couple of the wall sections after being cut out of a

sheet of coroplast. In case you are curious about the pink color, the

sheets these were cut from was part of a shipping container packaging

system for electronic assemblies. In the electronics industry materials

colored pink have been treated to prevent the build up of static

electricity. My former employer used this until the customer went away

at which time they discarded many sheets of this and I lugged a lot of

it home.

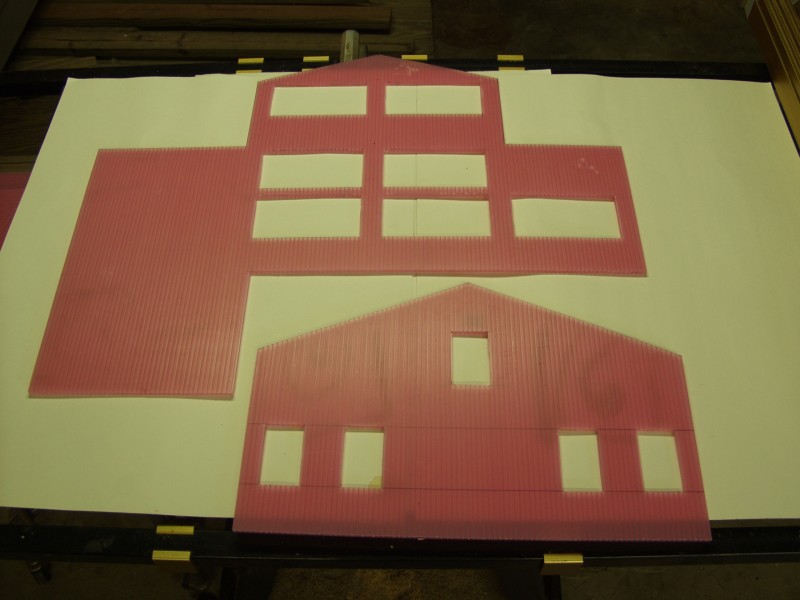

The

next photo shows how it was braced internally using 1/2" square PT

lumber which is glued on with a liquid nails type of product.

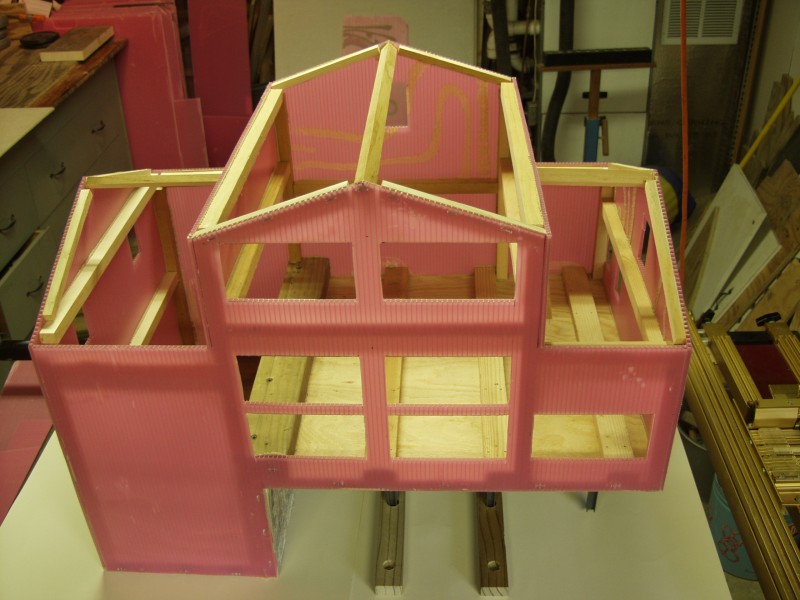

The

next photo shows most of the completed assembly before the roof was

installed. Strips were applied over the holes drilled in the base for

the 'H' columns to provide a solid stp for them. The 'H' columns

themselves are standard Plastruct 1/2" x 1/2" plastic 'H' material.

A

view from a different angle.

Unfortunately

I either didn't take and other assembly photos or I haven't located them

if I did. Once the windows and roof were installed and the building

sheathed with Precision Plastics sheets the building was moved outside

to make room for other projects. It sat outside on the layout for over

ten years then in 2017 it was due to be refreshed. Critters had pulled a

couple of the windows out and all sorts of debris found its way inside

including the usual insect varieties.

Updated

4/10/19